如果说VDA 6.3在汽车行业的地位像屠龙宝刀一样的话,那么作为新生代如日中天的偶像-特斯拉出品的供应商手册,则可以称为验厂审核的原子弹了。鉴于特斯拉的供应商管理手册仅门户网站的全英文版本为受控版本,所以本处的仅仅是通过公开渠道流传的06版本作为例子进行解析,为了方便理解,我们特意做了翻译和解释,如有错误,请多多包涵,并提出您的建议,本文章仅仅用于学习和分享。

Foreword 前言

Revision 06 of this document brings significant changes to both BMS-0000051 (this document) and BMS-0000258 (“Supplier Quality Assurance Manual”).

本文件的06版对BMS-0000051(本文件)和BMS-0000258(《供应商质量保证手册》)都做了重大修订。

As of this revision, the last revisions of BMS-0000051 and BMS-0000258 have been combined under the label BMS-0000051. As a result, BMS-0000258 is now obsolete.

自本次修订开始,BMS-0000051和BMS-0000258的最后修订已经合并为BMS-0000051,BMS-0000258现在作废。

Contents 目录

Section 1 Introduction

第一节 简介

Section2Document Purpose and Structure

第二节 文件目的和结构

Section 3 General Expectations & Procedures

第三节 通用期望和程序

3.1 Supplier Responsibilities 供应商责任

3.1.1 Senior Management Responsibilities 高级管理人员职责

3.1.2 Confidentiality 保密性

3.2 Quality Management System(QMS) Requirements 质量管理体系要求

3.2.1 Quality Activities 质量活动

3.3 Industry Standards 行业标准

Section 4 Supplier Assessment and Qualification

第四节 供应商评估和资格认证

4.1 Assessment and Qualification Process 评估和资格认证过程

4.1.1 Supplier Assessment 供应商评估

4.1.2 Supplier Qualification and Nomination 供应商资格认证和提名

4.1.3 Assessment Corrective Action评估纠正措施

4.2 Audit 审核

4.2.1 Process Audit 过程审核

4.2.2 Safety Critical Audits 安全关键审核

4.3 Supplier Risk 供应商风险

4.4 Supplier Performance Feedback 供应商绩效反馈

Section 5 General Requirements

第五节 通用要求

5.1 Safety & Critical Characteristic 安全和关键特性

5.1.1 Safety Critical Components and Characteristics 安全关键零件和特性

5.2 Change Control 变更控制

5.2.1 ECO-Engineer Change Order 工程变更单

5.2.2 PCR-Process Change Request过程变更申请

5.3 Control Plans 控制计划

5.4 MSA-Measurement System Analysis 测量系统分析

5.5 MPR-Mating Parts Request 配套零件要求

5.6 Transportation Requirements 运输要求

5.6.1 Package 包装

5.6.2 Labeling 标签

5.6.3 Preservation 防护

5.6.4 Shipping 发运

5.6.5 invoircing 开具发票

5.6.6 Certificate of Comliance 合格证书

5.7 Regulatory Compliance 监管合规

5.7.1Material RegulatoryComliance材料合规监管

5.8 Nonconforming Parts 不合格零件

5.8.1 Deviation Approval 偏差批准

5.8.2 SCAR-Supplier Corrective Action Request 供应商纠正措施要求

5.8.3 Product Containment/Controlled Shipping 产品遏制/受控发运

5.8.4 Warranty 售后

5.9 HVPT-High Volume Production Trial 大批量生产实验

Section 6 TQP-Tesla Qualification Process

第六节 特斯拉资格认证程序

6.1 Overview 总览

6.2 Specification 规格

6.2.1 Program Schedule 项目时间表

6.2.2 Inspection Standard 检验标准

6.2.3 Measurement System Analysis(MSA)for Equipment Proposal 设备提案的测量系统分析

6.2.4 Control Plan (Prototype) 控制计划(原型样件)

6.2.5 2D Drawing GD&T 2D图纸的形位公差

6.2.6 Design for Manufacturing (DFM) Complete 制造设计完成

6.3 Process Setp 过程准备

6.3.1 Process Flow Chart 过程流程图

6.3.2 PFMEA-Process Failure Mode and Effects Analysis 过程失效模式及后果分析

6.3.3 Control Plan(Production)控制计划(生产)

6.3.4 Measurement System Analysis(MSA)for Equipment Acceptance 设备验收的测量系统分析

6.4 Process Validation 过程确认

6.4.1 Measurement System Analysis(MSA)for Equipment Validation 设备确认的测量系统分析

6.4.2 Validation Testing 确认性测试

6.4.3 Capacity Study 产能研究

6.4.4 Capability Study 能力研究

6.4.5 SDS-Sample Data Sheet 样件数据表

6.4.6 AAR-Appearance Approval Report 外观批准报告

6.4.7 Packaging Plan 包装计划

6.4.8 Control Plan(Safe Launch)控制计划(安全启动)

6.5 Implementation 实施

6.5.1Material Regulatory Compliance Submissions 材料法规符合性提交

6.5.2 Safety Regulatory Compliance Submissions 安全监管合规提交

6.5.3 Tracibility 可追溯性

6.5.4 PFS-Problem Follow Sheet 问题跟踪表

6.5.5 TQP Approval TQP批准

Section 7 TQP-Appendix 附录

7.1 Abbreviation & Definition 缩写和定义

7.2 External Contact Information外部联络信息

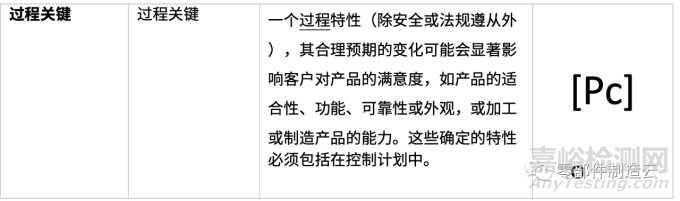

7.3 Critical Characteristic Symbols and Definitions 关键特性符号和定义

Section 8 Reference 参考文献

Section 1 Introduction

第一节 简介

The Supplier Handbook is intended for suppliers who directly supply parts and/or materials to Tesla. It serves to work in conjunction with relevant industry standards andto provide clarification of Tesla’s requirements and expectations.

本供应商手册是为直接向特斯拉提供零部件和/或材料的供应商而编写的。它的作用是与相关行业标准配合,并对特斯拉的要求和期望进行澄清。

Tesla is committed to operating as a world-class innovative leader, and to support that commitment, suppliers are chosen based on their operating excellence and methodologies. We frequently evaluate our suppliers and thoroughly look forward to doing continued business with those who have Tesla’s best interests in mind.

特斯拉致力于成为世界级的创新领导者,为了支持这一承诺,我们根据供应商的卓越运营和方法来选择他们。我们经常评估我们的供应商,并彻底期待着与那些将特斯拉的最佳利益放在心上的供应商继续开展业务。

As a business partner, your feedback is extremely valued and we encourage you to share your input on all areas covered in this and any other documents, or in any other aspects of our business. Site visits to Tesla are also encouraged and you should at all times feel free to provide feedback, whether minor or major.

作为商业伙伴,我们非常重视你的反馈意见,我们鼓励你分享你对本文件和其他任何文件中所涉及的所有领域,或我们业务的任何其他方面的意见。我们也鼓励对特斯拉进行实地考察,你应该在任何时候都能自由地提供反馈意见,无论是小事还是大事。

Section 2 Document Purpose and Structure

第二节 文件目的和结构

This document covers Tesla’s operating standards and aims to guide suppliers, step-bystep, towards a successful mass production program using the default tasks and stages.Tesla representatives are permitted to have suppliers deviate from some of these tasks,or part thereof, and may choose to do so if deemed appropriate.

本文件涵盖了特斯拉的运营标准,旨在通过默认的任务和阶段,一步一步地指导供应商成功实现大规模生产计划。特斯拉代表允许供应商偏离其中一些任务或部分任务,如果认为合适,可以选择这样做。

This and all pertaining documents should be read as soon as physically possible, to ensure a clear understanding for all who are involved of their responsibilities. Several documents are referenced throughout this document and may be found on the Supplier Portal, or as otherwise noted, if controlled by Tesla. Documents that are not controlled by Tesla, such as industry standards, must be obtained separately from an appropriate organization.

应尽快阅读本文件和所有相关文件,以确保所有相关人员清楚地了解其责任。本文件中引用了一些文件,可在供应商门户网站上找到,或在其他地方注明,如果由特斯拉控制。不受特斯拉控制的文件,如行业标准,必须单独从适当的组织获得。

This document is best viewed digitally to make use of internal links; individuals using a hard copy are responsible for ensuring that they are using the latest revision. Any future revisions become effective upon issuance to the supplier.

本文件最好以数字形式查看,以利用内部链接;使用硬拷贝的个人有责任确保他们使用的是最新版本。今后的任何修订在发给供应商时即生效。

Section 3 General Expectations & Procedures

第三节 通用期望和程序

3.1 Supplier Responsibilities 供应商责任

1. Suppliers are expected to provide 100% conforming products, on time and in the specified quantities, along with all required supporting data.

供应商应按时、按规定数量提供100%的合格产品,并提供所有必要的支持数据。

2. Suppliers shall immediately and openly communicate with Tesla any quality or delivery related problems and are expected to respond to issues immediately.

供应商应立即公开与特斯拉沟通任何与质量或交付有关的问题,并应立即对问题作出回应。

3. Suppliers shall leverage their expertise and provide feedback on part or process devised by Tesla to highlight concerns or improvements that could be made to meet quality requirements, reduce cost, time, yield, etc. Lack of feedback shall be deemed as acceptance of the design and process.

供应商应利用其专业知识,对特斯拉设计的零件或工艺提供反馈,以突出关注点或可进行的改进,以满足质量要求,降低成本、时间和产量等。缺乏反馈应被视为对设计和工艺的接受。

4. Suppliers are strongly encouraged to apply continuous improvement techniques that impact quality, service and cost.

我们强烈鼓励供应商应用影响质量、服务和成本的持续改进技术。

5. Suppliers shall maintain a contingency plan to satisfy Tesla’s requirements in the event of an emergency. These plans, and those of all sub-suppliers, are to be made available upon request to Tesla. Emergencies may include, but are not limited to, utility interruptions, labor shortages, key equipment failures and warranty returns.

供应商应保持一项应急计划,以满足特斯拉在紧急情况下的要求。这些计划以及所有次级供应商的计划应根据要求提供给特斯拉。紧急情况可能包括但不限于公用事业中断、劳动力短缺、关键设备故障和保修退货。

3.1.1 Senior Management Responsibilities

高级管理人员职责

Supplier Senior Management shall:

供应商高级管理层应:

1. Oversee the quality planning and quality system activities as well as all regulatory compliance activities.

监督质量策划和质量体系活动,以及所有法规遵从活动

2. Ensure all Tesla documentation is understood and followed within the supplier’s organization.

确保在供应商的组织范围内理解和遵守所有特斯拉文件。

3. Ensure adequate resources are provided to meet all Tesla requirements and all related departments are trained in regards to the requirements and guidelines of this document.

确保提供足够的资源以满足所有特斯拉的要求,并对所有相关部门进行有关

本文件要求和准则的培训。

4. Ensure the control and retention of document copies and any subsequent revisions provided by Tesla.

确保控制和保留文件副本和特斯拉提供的任何后续修订。

5. Oversee quality of communication and documentation released to Tesla and ensure clear and concise information and information integrity.

监督向特斯拉发布的通信和文件的质量,确保信息的清晰和简洁以及信息的完整性。

6. Ensure control and retention of documentation regarding regulatory compliance for the time periods required by specific regulations (up to 30 years after end of production in some cases).

确保在特定法规要求的时间段内(在某些情况下,生产结束后长达30年)控制和保留有关法规遵守的文件。

3.1.2 Confidentiality 保密性

In addition to the Non-Disclosure Agreement, the following is required:

除《保密协议》外,还需遵守以下规定:

1. The Supplier shall establish a system to manage confidentiality that begins at sourcing decision and continues through the life of the part.

供应商应建立一个从采购决策开始并持续到零件寿命的保密管理制度。

2. Any data, information, or knowledge (general and specific) obtained through activities with Tesla shall be securely controlled, treated with strict confidence,and properly destroyed when no longer necessary.

通过与特斯拉的活动获得的任何数据、信息或知识(一般的和具体的)应受到安全控制,严格保密,并在不再需要时适当销毁。

3. Any breach of confidentiality, or concerns, must be reported to Tesla management immediately.

任何违反保密规定的行为或担忧,都必须立即报告给特斯拉管理层。

3.2 Quality Management System(QMS) Requirements 质量管理体系要求

1. The quality system shall be defined and documented to describe the requirements for all quality related activities.

应定义和记录质量体系,以描述所有与质量有关的活动的要求。

2. The supplier shall establish, document, and maintain a quality management system as a means of ensuring that the product conforms to the specified requirements.

供应商应建立、记录并保持一个质量管理体系,作为确保产品符合规定要求的手段。

3. Quality records shall be maintained to demonstrate conformance to specified requirements and the effective operation of the quality system.应保持质量记录以证明符合规定的要求和质量体系的有效运行。

4. The quality system shall ensure all quality activities have been properly

implemented during trial builds and monitored thereafter.

质量体系应确保所有质量活动在试建期间得到适当的实施,并在此后进行监测。

5. The system shall, at a minimum, meet Tesla’s Supplier Handbook requirements. It is also desired that the quality system is certified to the ISO 9001 and/or ISO/TS 16949 standards.

该系统应至少满足特斯拉供应商手册的要求。此外,还希望该质量体系获得ISO 9001和/或ISO/TS16949标准的认证。

6. Quality Reporting 质量报告:

The supplier shall use the Supplier Portal to submit all required documentation and evidence.

供应商应使用供应商门户网站提交所有要求的文件和证据。

The supplier will also receive approval for individual tasks and part status through the Supplier Portal.

供应商还将通过供应商门户网站获得对个别任务和零件状态的批准。

Extra data designated by Tesla may be required to be reported

特斯拉指定的额外数据可能需要报告。

3.2.1 Quality Activities 质量活动

The supplier is responsible for the following activities needed to ensure products are consistently manufactured to Tesla requirements.

供应商负责以下所需活动,以确保产品的生产始终符合特斯拉的要求。

1. Program Schedule 项目计划

- The supplier shall establish advanced quality planning as part of the overall program based on timing provided by Tesla.

供应商应根据特斯拉提供的时间,建立先期质量策划,作为整体项目的一部分。

2. Process Monitoring and Operator Instructions 过程监控和操作说明

- The supplier shall prepare documented process monitoring and operator

instructions for all employees having responsibilities for operation of a

process or processes.

供应商应为所有负责操作某项或多项过程的员工编制成文的过程监测和操作说明。

- These instructions shall be accessible at the workstation and include proper visual aids.

这些说明应可在工作站获得,并包括适当的视觉辅助教具。

3. Verification of Equipment Set-ups 设备作业准备的验证

- Equipment set-ups shall be verified whenever a set-up is performed (e.g.,initial run of a lot, material changeover, tool change, etc.).

每当进行作业准备时(例如,一个批次的初始运行、材料更换、工具更换等),都应验证设备作业准备情况。

- Change-over instructions shall be available for set-up personnel.

更换指导应当就位可供准备人员使用。

- First-off, last-off part comparisons are recommended.

推荐使用首件、末件对比。

4. Receiving Inspection 收货检验

- The supplier shall ensure incoming product is inspected, or otherwise verified, as conforming to specified requirements.

供应商应确保对进货产品进行检查,或以其他方式验证其是否符合规定要求。

5. In-Process Inspection and Test 过程检验和测试

- The supplier shall inspect and test the in-process product as required by the relevant control plan or documented procedures.

供应商应按照相关控制计划或文件化程序的要求检查和测试在制品。

6. Final Inspection and Test 最终检验和测试

- The supplier shall carry out all final inspections and testing in accordance with the relevant control plan or documented procedures.

供应商应按照相关的控制计划或文件化的程序进行所有的最终和测试。

7. Inspection and Test Records 检验和测试记录

- The supplier shall establish and maintain records which provide evidence that the product has been inspected and/or tested.

供应商应建立并保存记录,以证明产品已经过检查和/或测试。

8. Inspection Measuring and Test Equipment 检验测量和测试设备

- The supplier shall establish and maintain documented procedures to control, calibrate, and maintain inspection, measurement and testing equipment.

供应商应建立和维护形成文件的程序,以控制、校准和维护检验、测量和测试设备。

9. Internal Quality Audits 内部质量审核

- The supplier shall plan and implement internal quality audits to verify whether quality activities and related results comply with planned arrangements.

供应商应计划并实施内部质量审核,以验证质量活动和相关结果是否符合计划安排。

- Results shall be made available to Tesla upon request.

应根据要求向特斯拉提供结果。

10. Quality Records 质量记录

- Quality records shall be maintained to demonstrate conformance to specified requirements and the effective operation of the quality system.应保持质量记录以证明符合规定的要求和质量体系的有效运行。

11. Engineering Change Order (ECO) Implementation

工程变更单(ECO)的实施

- The supplier shall have a system in place for the control and implementation of Engineering Changes. Process flow and standard timing must be made available on request.

供应商应建立一个控制和实施工程变更的系统。必须根据要求提供变更流程和标准时间。

12. Process Change Implementation 过程变更的实施

- The supplier shall have a system in place for the control and implementation of process changes.

供应商应建立一个控制和实施过程变更的系统。

13. Nonconforming Parts 不合格零件

- The supplier shall establish and maintain documented procedures to ensure that parts which do not conform to specified requirements are

prevented from unintended use, installation or shipment.

供应商应建立并保持形成文件的程序,以防止不符合规定要求的部件被意外使用、安装或发运。

14. Packaging, Labeling, Preservation and Shipping

包装、标签、防护和发运

- The supplier shall establish and maintain documented procedures for handling, storage, packaging, preservation and delivery of product.

供应商应建立并保持关于产品的处理、储存、包装、防护和交付的文件化的程序。

15. Training and Qualification of Team Members

团队成员的培训和资格认证

- The supplier shall effectively manage a comprehensive training program

for all employees. Individual needs shall be identified through an evaluation process that includes references to retained employee training records.

供应商应有效管理针对所有员工的综合培训计划。应通过评估过程来确定个人需求,包括参考所保留的员工培训记录。

- Employees working on Tesla projects are expected to have completed a

comprehensive training program which focuses on developing the employees’ capabilities and motivation.

从事特斯拉项目的员工应已完成全面的培训计划,该计划的重点是发展员工的能力和动力。

- All training necessary to meet Tesla objectives shall be completed by the first off process trial.

所有达到特斯拉目标所需的培训都应在第一次试生产前完成。

- The supplier should develop a method for documenting team members'

progress and capability.

供应商应制定一种方法来记录团队成员的进步和能力。

16. Identification and Traceability 标识和可追溯性

- The supplier is responsible for preparing the Inspection Standard. Identification and Traceability information should be included in the

original draft.

供应商负责准备检验标准。标识和可追溯性信息应包括在原始草案中。

- Identification and Traceability actions must comply with the requirements set on the Engineering Drawing and/or Inspection Standard.

标识和追溯行动必须符合工程图和/或检验标准中规定的要求。

- Identification 标识

The supplier must adhere to the identification requirements specified on

the part drawing or Inspection Standard. In cases where there is no specification, the supplier must work closely with Tesla to determine the appropriate level of identification that must be agreed upon.

供应商必须遵守零件图纸或检验标准中规定的标识要求。在没有规范的情况下,供应商必须与特斯拉紧密合作,以确定必须遵守的适当的标识等级。

- Traceability 可追溯性

Each supplier must control the traceability of their own and sub-suppliers

products, from received raw materials through shipping. Where appropriate, suppliers are encouraged to add serial numbers, or other forms of traceability to each part.

每个供应商必须控制他们自己和次级供应商产品的可追溯性,从收到原材料到运输。在适当的情况下,鼓励供应商在每个零件上添加序列号,或其他形式的可追溯性。

17. Sub-Supplier Control 子供应商控制

- The role of the Tier 1 supplier in coordinating and guiding all sub-supplier quality assurance activities must be similar to the Tier 1 suppliers’

requirements in this document.

一级供应商在协调和指导所有次级供应商质量保证活动方面的作用必须与本文件中一级供应商的要求相似。

- The Tier 1 supplier is responsible for the part quality and production readiness of all sub-supplier’s (directed by Tesla or otherwise), as well as

evaluating all sub-supplier's parts / materials and conducting quality approvals.

一级供应商负责所有次级供应商(由特斯拉指定或其他)的零件质量和生产准备,以及评估所有次级供应商的零件/材料并进行质量审批。

- Tesla MUST NOT be delayed by a sub-supplier being unprepared for Mass Production start-up.

特斯拉绝对不能因为次级供应商没有为批量生产的启动做好准备而延误。

18. Supplier Contact Sheet 供应商联络表

- A Supplier contact sheet shall be submitted to Tesla to identify key

personnel to be contacted in the event of a quality problem or concern.

应向特斯拉提交一份供应商联系表,以确定在出现质量问题或担心时

可联系的关键人员。

- The contact sheet shall be re-submitted to Tesla as changes occur.

联系表应在发生变化时重新提交给特斯拉。

19. Annual Validation 年度确认

- Suppliers may be required to perform annual assessments per the direction of Tesla.

供应商可能被要求按照特斯拉的规定进行年度评估。

- Assessments may include, but are not limited to: On-Going Reliability

Testing (ORT), layout, testing as possibility, etc.

评估可能包括,但不限于:持续的可靠性测试(ORT),布局,测试的可能性等等。

20. Regulatory Compliance Management Process (RCMP)

监管合规管理流程

- Suppliers shall implement an RCMP to ensure that pertinent product substance data is gathered from their supply chains, reviewed for accuracy and adherence to data structure requirements, consolidated into a single compliance profile for each product and submitted to Tesla in a timely manner.

供应商应实施RCMP,以确保从其供应链中收集相关的产品物质数据,审查其准确性和对数据结构要求的遵守情况,并将每个产品的合规情况汇总到一个单一的档案中,并及时提交给特斯拉。

3.3 Industry Standards 行业标准

Where applicable to their business, suppliers shall maintain the latest revisions of the standards shown below. Applicable assessments must be conducted annually at a minimum and the results made available to Tesla.在适用于其业务的情况下,供应商应保持下列标准的最新修订版。适用的评估必须至少每年进行一次,并将评估结果提供给特斯拉。

1. AIAG - Advanced Product Quality Planning (APQP) and Control Plan

先期产品质量策划和控制计划

2. AIAG - Failure Mode & Effects Analysis (FMEA) Reference Manual

失效模式计后果影响分析(FMEA)

3. AIAG - Measurement Systems Analysis (MSA) Reference Manual

测量系统分析(MSA)

4. AIAG - Production Part Approval Process (PPAP) 生产零件批准程序

5. AIAG - Statistical Process Control (SPC) 统计过程控制

6. CQI-09 - Heat Treat System Assessment 热处理系统评估

7. CQI-11 - Special Process: Plating System Assessment

特殊工艺:电镀系统评估

8. CQI-12 - Coating System Assessment 涂装系统评估

9. CQI-15 - Welding System Assessment 焊接系统评估

10.CQI-17 - Special Process: Soldering System Assessment

特殊工艺:锡焊系统评估

11.CQI-23 - Molding System Assessmet 注塑系统评估

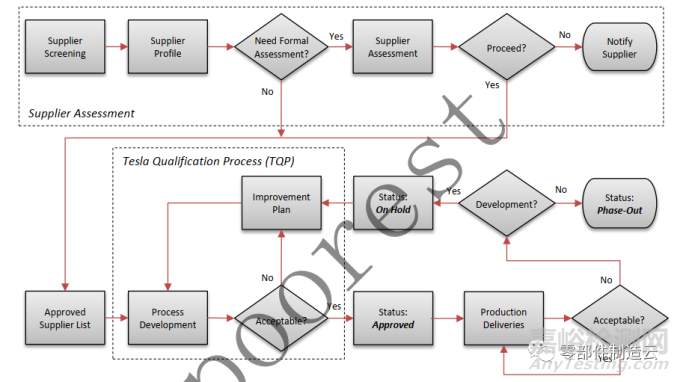

Section 4 Supplier Assessment and Qualification

第四节 供应商评估和资格认证

The following is a guideline of the requirements for supplier evaluations, including use of Tesla sourcing, parts and process audits, process sign-off audits and supplier feedback.

以下是对供应商评估要求的指导,包括使用特斯拉采购、零件和过程审核、过程验收审核和供应商反馈。

4.1 Assessment and Qualification Process 评估和资格认证过程

4.1.1 Supplier Assessment 供应商评估

An on-site evaluation may be performed during Tesla’s planning stage for each potential new supplier, in order to estimate the level of success of the program associated with each supplier. When the assessment is complete, the total score will be categorized as follows:

在特斯拉的计划阶段,可对每个潜在的新供应商进行现场评估,以估计与每个供应商相关的计划的成功水平。评估完成后,总分将被分类如下:

|

91% - 100% |

Exceptional 卓越供应商 |

|

81% - 90% |

Preferred Supplier 首选供应商 |

|

71% - 80% |

Good Supplier 良好供应商 |

|

61% - 70% |

Fair Supplier 中等供应商 |

|

< 60% |

Unacceptable 不接受 |

4.1.2 Supplier Qualification and Nomination 供应商资格认证和提名

The criteria for evaluation will consider the following:

评价的标准将考虑以下几点

- Engineering 工程

- Financial Stability 财务稳定性

- Logistics 物流

- Manufacturing Processes 制造过程

- Piece Price Cost 单件价格成本

- Program Management 项目管理

- Quality 质量

- Supplier Management 供应商管理

- Tool Cost 工具成本

- Tool Management 工具管理

The result of the sourcing audit (if required) will be considered during the supplier nomination process. If the assessment shows satisfactory results and all commercial points are in order, the supplier will be qualified and added to Tesla’s approved suppliers list。

采购审核的结果(如果需要)将在供应商提名过程中得到考虑。如果评估结果令人满意,且所有商业点都符合要求,则该供应商将获得资格,并被列入特斯拉的认可供应商名单。

4.1.3 Assessment Corrective Action 评估纠正措施

1. In the event the assessment reveals that corrective actions must be completed before a supplier can be qualified, an action plan will be requested from the supplier for the elements that were identified during the assessment.

如果评估显示,在供应商获得资格之前必须完成纠正措施,则将要求供应商

就评估中发现的内容提供行动计划。

2. The supplier shall provide a corrective action plan to Tesla within 14 days of notification, stating clearly the corrective actions to be taken and indicating the planned implementation date for each corrective action.

供应商应在接到通知后的14天内向特斯拉提供一份纠正措施计划,明确说明

将采取的纠正措施,并指出每项纠正措施的计划实施日期。

3. The supplier shall update Tesla at planned intervals on the progress for the corrective action.

供应商应按计划的时间间隔向特斯拉更新纠正措施的进展。

4. The supplier shall notify Tesla when all corrective actions have been implemented.

供应商应在所有纠正措施实施完毕后通知特斯拉。

5. Once the corrective action implementation is complete, Tesla may decide to reaudit the supplier. Alternatively, verification of the corrective actions may take place during subsequent audits.

一旦纠正措施实施完毕,特斯拉可决定对该供应商进行重新审核。另外,在

随后的审核中也可对纠正措施进行验证。

4.2 Audits 审核

4.2.1 Process Audits 过程审核

- During New Product Introduction (NPI) or modification, Tesla may decide to carry out a process audit. This audit covers both documentation and process implementation, and will be carried out at a suitable point in time.

在新产品引进(NPI)或修改期间,特斯拉可能决定进行过程审核。该审核包括文件和过程实施,并将在一个合适的时间点进行。

- Tesla may decide to re-audit once all corrective actions have been implemented or at an appropriate point in time.

特斯可能决定在所有纠正措施实施后或在一个适当的时间点重新进行审核。

- Suppliers must assign an internal audit champion responsible for conducting, at minimum, annual audits to ensure all processes meet Tesla’s requirements.

供应商必须指定一名内部审核负责人,负责在以下方面进行审核,至少要进行年度审核,以确保所有过程符合特斯拉的要求。

4.2.2 Safety Critical Audits 安全关键审核

Tesla will carry out audits on safety critical components and processes, at intervals deemed necessary by Tesla. As a result of the audit, the supplier may be issued with nonconformances. The Supplier shall be required to develop and submit a corrective action plan to Tesla within 14 days of the audit. The supplier shall provide regular updates on corrective action and implementation until the issues are closed.

特斯拉将按照特斯拉认为必要的时间间隔,对安全关键零件和过程进行审核。作为审核的结果,供应商可能会被发出不符合要求的通知。供应商应被要求在审核后14天内制定并向特斯拉提交一份纠正措施计划。供应商应定期提供有关纠正措施和实施的最新情况,直至问题得到解决。

4.3 Supplier Risk 供应商风险

Suppliers may be assessed on their risk to the overall success of a Tesla project. Suppliers that are deemed a risk, or a potential risk, may be required to participate in additional monitoring and development activities, as decided appropriate by Tesla.

供应商可能会被评估其对特斯拉项目的整体成功的风险。被认为是风险或潜在风险的供应商,可能被要求参与特斯拉决定的额外监测和开发活动。

4.4 Supplier Performance Feedback 供应商业绩反馈

Suppliers will be provided with feedback and assigned a score according to their performance. Poor performance can result in disqualification of the supplier and removal from Tesla’s approved suppliers List. Suppliers may be asked to supply a corrective action plan addressing problem areas in order to remain eligible for continued or future business. Suppliers will be assigned one of four following classifications as a result of their ongoing performance.

供应商将得到反馈,并根据他们的表现分配一个分数。表现不佳的供应商可能会被取消资格,并从特斯拉批准的供应商名单中删除。供应商可能会被要求提供一份针对问题领域的纠正措施计划,以保持继续或未来业务的资格。根据供应商的持续表现,他们将被分配到以下四个分类中的一个

1. Preferred: Strategic relationship built on a variety of factors.

首选:建立在各种因素上的战略关系。

2. Approved: Supplier meets quality and service requirements.

批准:供应商符合质量和服务要求。

3. On Hold: Supplier won’t receive new business until issues are resolved. 暂停:在问题得到解决之前, 供应商不会收到新的业务

4. Phase Out: Supplier will eventually no longer be used to supply selected part.

淘汰:供应商最终将不再被用于供应选定的零件。

Section 5 General Requirements

第五节 通用要求

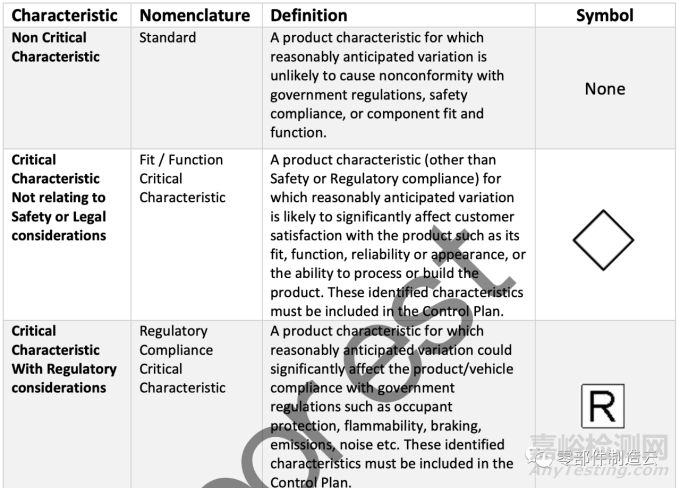

5.1 Safety & Critical Characteristics 安全和关键特性

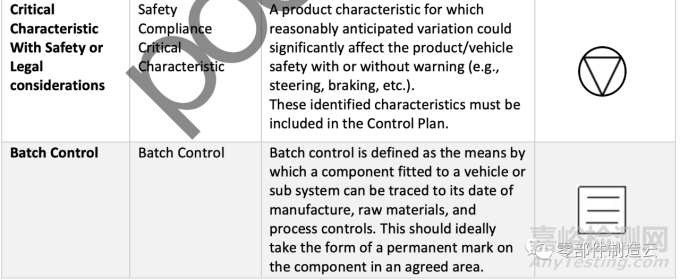

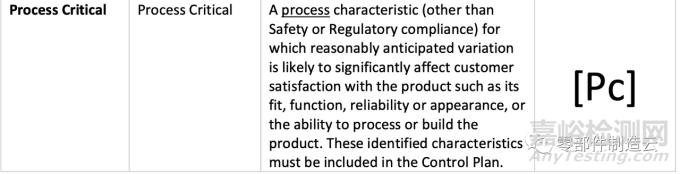

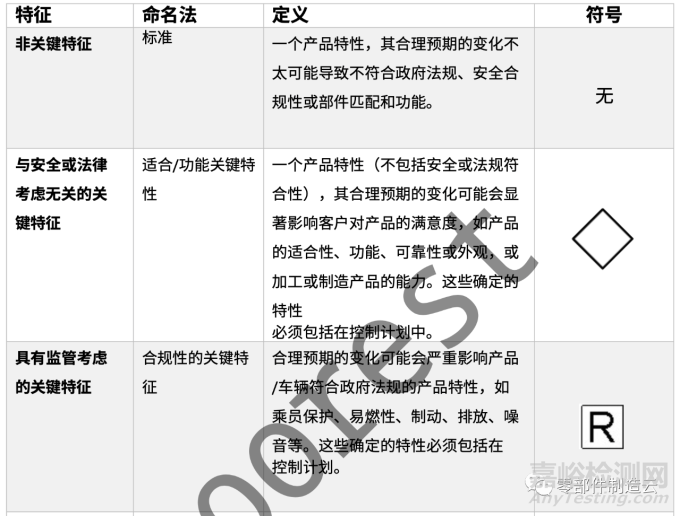

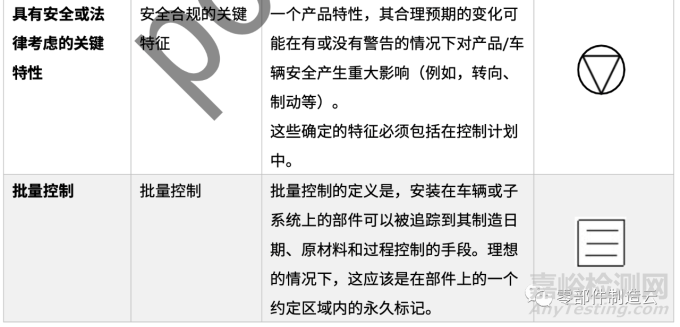

1. Critical characteristics shall be identified based on features that are critical to safety, reliability, function or fit and/or by FMEA methods to identify important features of high risk.

关键特性应根据对安全性、可靠性、功能或适应性至关重要的特性和/或通

过FMEA方法来确定高风险的重要特性。

2. Critical characteristics shall be identified on the Drawing and Inspection Standard using the symbols in Section 7.3

关键特性应使用第7.3节中的符号在图纸和检验标准上进行标识。

3. For critical features, Tesla requires the submission of Process Performance (Ppk) data for trial builds and Process Capability (Cpk) data for parts produced after start of production (refer Section 6.4.4 for details). Trial builds include all builds from the prototype stage through start of production.

对于关键特征,特斯拉要求提交试制的过程性能(Ppk) 数据和生产开始后生产的零件的过程能力(Cpk)数据(详见6.4.4节)。试制包括从原型样件阶段到量产的所有构建。

4. Suppliers must identify critical characteristics on their Inspection Standards, Control Plans, Work Instructions, Process Flow Charts, and other relevant documentation also using the symbols shown in Section

供应商必须在其检验标准、控制计划、作业指导书、过程流程图和其他相关

文件中也使用第7.3节所示的符号来识别关键特征。

5.1.1 Safety Critical Components and Characteristics

安全关键部件和特性

Tesla requires suppliers of safety critical components (components that contain safety critical characteristics, as indicated on the components drawing using the symbols defined in Section 7.3) to demonstrate that they control all aspects of the manufacturing process. The following requirements shall apply:

特斯拉要求安全关键部件(包含安全关键特性的部件,在部件图纸上使用第7.3节中定义的符号表示)的供应商证明他们控制了制造过程的所有方面。应适用以下要求:

1. When assigning personnel to the production of a safety critical component, the supplier shall:在指派人员生产安全关键部件时,供应商应

- Ensure that all personnel involved in the manufacturing and testing of

these components have completed designated training and demonstrate

the required level of skill and knowledge to carry out the process.

确保所有参与制造和测试这些部件的人员都已完成指定的培训,并表现出所需的技能和知识水平,以执行该过程。

- Maintain training records for all employees that clearly show the employees ability to work on a product with safety critical characteristics.

保持所有员工的培训记录,明确显示员工有能力在具有安全关键特性的产品上工作。

2. All test equipment used to verify a safety critical component shall be listed on the Control Plans.

所有用于验证安全关键部件的测试设备应在控制计划中列出。

3. All test equipment and machinery used in the manufacturing of a safety critical component have an associated preventative maintenance plan.

所有用于制造安全关键部件的测试设备和机器都有相关的预防性维护计划。

4. No alterations to the manufacturing process are permitted without approval from Tesla. Approval must be obtained prior to shipment of parts and may require a new Tesla Qualification Process (TQP) submission; refer Section 6 for details.

未经特斯拉批准,不得对制造过程进行改动。必须在零件装运前获得批准,并可能需要提交新的特斯拉资格认证程序(TQP);详情请参阅第6节。

5. The supplier shall audit processes used to produce safety critical components at regular intervals. Records shall be available to show the audit findings and corrective actions.

供应商应定期审核用于生产安全关键部件的过程。应提供记录以显示审核结果和纠正措施。

6. Where safety critical characteristics are subject to a sub-supplier’s process control plan, Tesla requirements shall be applied to the sub-supplier.

当安全关键特性受制于次级供应商的过程控制时计划,特斯拉的要求应适用于分供方。

7. The supplier shall be able to demonstrate process capability for processes used to produce parts with safety critical characteristics. Each characteristic must have a Process Capability, in accordance with requirements in Section 6.4.4, or documented inspection and / or verification date to show appropriate process control.

供应商应能证明用于生产具有安全关键特性的零件的过程的过程能力。根据第6.4.4节的要求,每个特性都必须有一个过程能力,或有记录的检查和/或验证日期,以显示适当的过程控制。

8. Notification must be provided for any rework that could impact a safety critical characteristic. Where practical, a Tesla approved indelible mark shall be used to identify reworked parts. All records shall be retained for part identification.

对于任何可能影响安全关键特性的返工,必须提供通知。在可行的情况下,应使用特斯拉批准的永久标记来识别返工的部件。所有的记录都应保留,以便识别零件。

9. Safety critical components have batch control and/or traceability requirements which must be met, as outlined in BMS-0000151 -Traceability Specifications.

安全关键部件具有必须满足的批次控制和/或可追溯性要求,如 BMS-0000151-可追溯性规范中所述。

5.2 Change Control 变更控制

5.2.1 ECO - Engineering Change Order 工程变更单

ECO’s are issued to suppliers by Tesla for changes to the design drawing or specifications.They can apply to any part, from the time of drawing issuance through the life of the part.

特斯拉向供应商发放ECO,用于更改设计图纸或规格。它们可以适用于任何部件,从图纸发布之时到零件的生命周期。

1. The supplier shall have a system in place for the control and implementation of engineering changes.

供应商应建立一个控制和实施工程变更的系统。

2. The supplier must receive approval of their project plan prior to the start of implementation.

在开始实施之前,供应商必须得到其项目计划的批准。

3. Prior to implementation of an ECO, it is the supplier's responsibility to update any internal standards, Inspection Standards, Control Plans, etc. to reflect ECO changes and submit to Tesla for approval.

在实施ECO之前,供应商有责任更新任何内部标准、检验标准、控制计划等,以反映ECO的变化,并提交给特斯拉进行审批。

4. ECO’s should be implemented in a timely manner, in accordance with instructions from Tesla.

ECO应按照Tesla的指示及时实施。

5. ECO’s shall not increase the applicable Purchase Price or change the applicable Schedule unless such change is expressly approved in writing by an authorized Tesla representative.

除非得到特斯拉授权代表的明确书面批准,否则ECO's不得提高适用的购买

价格或改变适用的时间表。

5.2.2 PCR - Process Change Request - 过程变更请求

PCR’s are used to ensure part quality by identifying and controlling any process changes following initial TQP approval, and to ensure adequate communication with Tesla.

PCR用于识别和控制最初TQP批准后的任何过程变化,以确保零件质量,并确保与Tesla的充分沟通。

1. The following are guidelines only, subject to Tesla approval:

以下仅是指导方针,须经特斯拉批准:

a. PCR approval is required for: 以下情况需要PCR的批准

- Addition or replacement of tooling or machines for mass production.

增加或更换用于大规模生产的工具或机器。

- Manufacturing location changes within a plant or to a new location.

在一个工厂内改变制造地点,或到一个新的地点。

- Significant manpower change (additional shift, etc.)

重大的人力变化(增加班次等)。

- Changes in approved production process, tooling and/or layout, process

flow, inspection & testing etc. in sub-supplier approved production

processes.

在次级供应商批准的生产过程中,对批准的生产过程、工具和/或布局、工艺流程、检查和测试等的改变。

- Change of sub-supplier for parts or raw materials.

改变零件或原材料的次级供应商。

b. PCR approval is not required for:

以下情况不需要PCR的批准:

- Relocation of small tools, jigs, fixtures that are not part of the main

production line and do not affect process or part quality.

搬迁不属于主要生产线且不影响过程或零件质量的小型工具、夹具、固定装置。

- Regular replacement of perishable tools or preventative/predictive

maintenance.

定期更换易损工具或进行预防性/预测性维护。

- Minor day-to-day Kaizen activity.

小型的日常改善活动。

2. The “Completed by Supplier” portion of the Plan Stage on the PCR form, along with supporting documentation, is to be completed and submitted to Tesla in advance. The supplier must not proceed with any process change without having approval from Tesla on the PCR.

PCR表格中计划阶段的 "由供应商完成 "部分,连同支持性文件,应提前完成并提交给特斯拉。在未得到特斯拉对PCR的批准之前,供应商不得进行任何过程变更。

3. Tesla will determine what requirements (trial quantity, documents, data, etc.) will be necessary for PCR approval.

特斯拉将确定对PCR的批准有哪些要求(试验数量、文件、数据等)。

4. The required parts/data will be reviewed by Tesla and a decision made whether to proceed with a trial or mass production; neither can begin until an approved PCR is received from Tesla.

所需的部件/数据将由特斯拉审查,并决定是否进行试验或大规模生产;在收到特斯拉批准的PCR之前,两者都不能开始。

5. The “Mass Production” section of the PCR must be completed and sent to Tesla prior to the initial shipment.

必须填写PCR的 "大规模生产 "部分,并在首次装运前将其发送给特斯拉。

6. Tesla will record the initial vehicle number, sign and return the completed PCR to the supplier.

特斯拉将记录最初的车辆编号,签署并将完成的PCR返回给供应商。

7. PCR’s shall not increase the applicable Purchase Price or change the applicable Schedule unless such change is expressly approved in writing by an authorized Tesla representative.

除非得到特斯拉授权代表的明确书面批准,否则PCR公司不得提高适用的购买价格或改变适用的时间表。

5.3 Control Plans 控制计划

A Control Plan is used to define all key process and part control points, control criteria such as location, target, method and frequency of checks, from incoming material to shipping of finished goods. It is recommended that the supplier use cross functional teams to develop any Control Plans.控制计划是用来定义所有关键的过程和零件控制点,控制标准,如位置、目标、方法和检查频率,从进料到成品运输。建议供应商使用跨职能团队来制定任何控制计划。

1. The supplier shall prepare a Control Plan, as specified by Tesla, for all products supplied during a TQP development stage or stages. Several control plans are used throughout the TQP approval process and are detailed further in their respective locations.

供应商应按照特斯拉的规定,为在TQP开发阶段或各阶段提供的所有产品编制一份控制计划。在整个TQP审批过程中使用了若干控制计划,并在其各自的位置进一步详细说明。

2. The Control Plan should be updated as necessary for process changes or corrective actions.

控制计划应根据工艺变化或纠正措施的需要进行更新。

3. The Control Plan may be submitted in the supplier’s format; however, it must meet all of the requirements below:

控制计划可以用供应商的格式提交;但是,它必须满足以下所有要求:

- The identification of all special & critical Characteristics using the correct symbols.

使用正确的符号识别所有特殊和关键特征。

- The identification of other specific characteristics on the part inspection standard.

对零件检验标准的其他具体特征的鉴定。

- Identification of measurement equipment or data collection where applicable.

在适用的情况下,确定测量设备或数据收集。

- Detailed reaction plans with designated responsibilities.

有指定责任的详细反应计划。

- Process, machine, and part potential failure modes must be identified and utilized to develop the Control Plan in order to ensure that potential failure causes can be controlled and monitored.

必须确定并利用过程、机器和零件的潜在失效模式来制定控制计划,以确保潜在的失效原因能够得到控制和监测。

- The Control Plan should consist of additional controls, inspection audits, and testing to identify non-conformances during the production process.

控制计划应包括额外的控制、检验审核和测试,以确定生产过程中的不合格情况。

- Consideration should be given to the build quantities required when

establishing inspection frequencies.

在确定检查频率时,应考虑到所需的生产数量。

5.4 MSA - Measurement Systems Analysis 测量系统分析

1. Suppliers are expected to provide all technical staff and facilities required todevelop robust part and process control systems.

供应商应提供开发稳健的零件和过程控制系统所需的所有技术人员和设施。

- When control systems involve the acquisition of information (e.g.

measurement data), the supplier shall ensure the information is at a

quality level that allows for valid data analysis.

当控制系统涉及信息(如测量数据)的获取时,供应商应确保信息的质量水平能够进行有效的数据分析。

- The measurement system used to acquire part and process information

shall be developed, validated, and available for use to support all associated control plans and inspection standards.

用于获取零件和过程信息的测量系统应得到开发、确认,并可用于支持所有相关的控制计划和检验标准。

2. Suppliers shall adhere to all requirements set in the following standards, found on the Supplier Portal:

供应商应遵守以下标准中的所有要求,可在供应商门户网站上找到:

- TS-0003139 - Gauge and Check Fixture Standard 量具和检查夹具标准

- TS-0003403 - Dimensional Data Transfer 尺寸数据传输

- TS-0003413 - Measurement Systems Analysis Standard 测量系统分析

- TS-0003552 - GRR 量具重复性和再现性

- TS-0003687 - Gauge and Check Fixture Buyoff Check Sheet

量具和检查夹具买断检查表

- TS-0003986 - MDSS

3. Validation of the measurement system shall include, but is not limited to, evidence of calibration certification traceable to a national or international certifying body, control and maintenance planning, proper use instructions, and validation of the quality of data collected (e.g. GR&R).

测量系统的验证应包括但不限于可追溯到国家或国际认证机构的校准证明、控制和维护计划、正确的使用说明以及对所收集数据质量的验证(如GR&R)。

4. Suppliers must submit requests in writing to Tesla through the PCR process to obtain approval prior to implementing any changes. Changes may be needed as a result of:

供应商必须通过PCR程序向特斯拉提交书面请求,以便在实施任何变更之前获得批准。由于以下原因,可能需要进行更改:

- Engineering Change Order (ECO) 工程变更单

- Part Inspection Standard change 零件检验标准的改变

- Process change 过程变更

- Repair (major damage; outside of normal maintenance)

返修(重大损坏;正常维修之外的)

5. Before disposing of any Tesla owned equipment or tools (eg. checking fixtures,etc.), the supplier must contact their Tesla representative and receive written authorization.

在处理任何特斯拉拥有的设备或工具(如检查夹具等)之前,供应商必须与他们的特斯拉代表联系并获得书面授权。

5.5 MPR - Mating Parts Request 配套零件要求

The MPR form gives the supplier the opportunity to request parts for quality purposes. Tesla will provide mating parts when there is good reason, it is feasible, and cost effective. The Tesla format provided in BMS-0000259 - Supplier Quality Toolkit must be used.

MPR表格让供应商有机会为质量目的要求提供零件。特斯拉将在有充分理由、可行和具有成本效益的情况下提供配套零件。必须使用BMS-0000259 - 供应商质量工具包中提供的特斯拉格式。

1. Tesla will consider any MPR and respond by supplying mating parts, or a reasonfor declining the request.

特斯拉将考虑任何MPR,并通过提供匹配的零件或拒绝请求的理由作出回应.

2. Tesla will have the final decision regarding the necessity and use of mating parts.

特斯拉将对配合部件的必要性和使用有最终决定权。

3. If Tesla grants a mating part to a supplier, the supplier must ensure that the mating parts used for their testing and other purposes are always the latest version.

如果特斯拉将配套部件授予供应商,供应商必须确保用于其测试和其他目的

的配套部件始终是最新版本。

4. If there are significant changes to the supplier-provided part that substantiates a need for a new mating part, the supplier must submit a new request.

如果供应商提供的零件有重大变化,证明需要新的配合零件,供应商必须提

交新的申请。

5. Mating parts that have been provided must be returned to Tesla or disposed of as directed by Tesla.

已经提供的配套零件必须退回给特斯拉或按照特斯拉的指示进行处理。

5.6 Transportation Requirements 运输要求

To ensure part quality, the supplier shall establish a system to assure that all parts shipped to Tesla meet the below requirements. Documentation of all Tesla transportation requirements shall be maintained by Tesla’s part number.

为确保零件质量,供应商应建立一个系统,以确保运往特斯拉的所有零件符合以下要求。特斯拉所有运输要求的文件应按特斯拉的零件编号保存。

5.6.1 Packaging 包装

1. Tesla standards Packaging Material and Equipment Codes, Domestic Expandable Standards and Overseas Expendable Standards shall be followed.

应遵循特斯拉标准《包装材料和设备规范》、《国内可扩展标准》和《海外消耗品标准》。

- All pack size, packaging, container or pallet dimensions and/or type shall be pre-approved by the appropriate Tesla representative(s).

所有的包装尺寸、包装、容器或托盘的尺寸和/或类型应事先得到特斯拉有关代表的批准。

- The supplier must receive approval for temporary use of packaging which does not meet requirements.

如果临时使用不符合要求的包装,供应商必须得到批准。

2. Considerations must be taken when selecting packaging types to ensure adequate part protection, safety concerning hazardous materials and cost are adequately addressed.

在选择包装类型时,必须考虑到确保充分的部件保护、有关危险材料的安全和成本得到充分解决。

3. Submission requirements may be found under Section 6.4.7.

提交要求可在第6.4.7节中找到。

4. Tesla packaging standards for both Domestic Expendable Packaging and Overseas Expendable Packaging are located on the Supplier Portal. Labeling procedures should have annual audits of label content to confirm that all information on the label is correct and up to date.

国内消耗性包装和海外消耗性包装的特斯拉包装标准都位于供应商门户网站上。

5.6.2 Labeling 标签

There are two methods to comply with Tesla’s labeling requirements:

有两种方法可以遵守特斯拉的标签要求:

1. Suppliers providing advance shipment data via the Supplier Portal must print the shipping labels directly from the Portal and attach to the Product (Pallet and Box labels). No other label formats will be considered compliant.

供应商通过供应商门户网站提供预先装运数据,必须直接从门户网站打印装运标签并附在产品上(托盘和箱子标签)。其他标签格式将不被视为合规。

2. Suppliers providing advance shipment data via ASN EDI must generate their own shipping labels (Pallet and Box) according to Tesla Standards BMS-0000003 - Shipping Label Specification and submit the labels for approval by the Tesla EDI team. (Please reach out to TeslaEDI@teslamotors.com for more detail).

供应商通过ASN EDI提供预先发货数据,必须根据特斯拉标准BMS-0000003-发货标签规范生成自己的发货标签(托盘和箱子),并提交标签供特斯拉EDI团队批准。(请联系 TeslaEDI@teslamotors.com 以了解更多细节)。

Labeling procedures should have annual audits of label content to confirm that all information on the label is correct and up to date.

标签程序应该对标签内容进行年度审计,以确认标签上的所有信息都是正确和最新的。

5.6.3 Preservation 防护

1. The supplier shall establish and maintain a material handling system that eliminates the potential for damage throughout all operations and transportation to Tesla facilities.

应商应建立和维护一个材料处理系统,在所有操作和运输到特斯拉设施的过程中消除损坏的可能性。

2. The supplier shall systematically review material handling processes and equipment to prevent damage to in-process parts and finished goods.供应商应系统地审查材料处理过程和设备,以防止对在制品和成品的损害。

3. Adhesives and other perishable or environmentally sensitive products should be stored and transported in the appropriate environmental conditions.

粘合剂和其他易腐烂或环境敏感的产品应在适当的环境条件下储存和运输。

4. Suppliers should consider Tesla usage in order to maintain the required shelf life for material performance.

供应商应考虑特斯拉的使用,以保持材料性能所需的保质期。

5.6.4 Shipping 发运

1. The supplier shall ship all materials in conformance with Tesla transportation routings.

供应商应按照特斯拉的运输路线运送所有材料。

2. The supplier shall maintain a file that includes documentation demonstrating that it has adhered to specified routings and shipping methods.

供应商应保存一份档案,其中包括证明其遵守规定路线和运输方法的文件。

3. The supplier shall have facilities adequate for shipping and receiving operations; at a minimum, the supplier shall assure that the number of doors / bays is adequate for shipping and receiving schedules, and that dock areas are well-lit and maintained with enough space for shipping and receiving activities.

供应商应拥有足够的设施用于装运和接收业务;至少,供应商应保证门/托架的数量是码头区照明良好,并有足够的空间供装运和接收活动使用。

4. The supplier is responsible for the loading, blocking, and bracing of cargo at the time of loading. For ocean or intermodal truck/rail shipment modes, the supplier is required to have appropriate load blocking and bracing supplies, and trained staff to facilitate timely loading. The mode of transit is determined by Tesla Logistics. Logistic_Inbound@tesla.com should be contacted with any questions.

供应商负责在装货时对货物进行装载、阻挡和支撑。对于海运或多式联运的卡车/铁路运输模式,供应商需要有适当的货物阻挡和支撑用品,以及训练有素的工作人员,以促进及时装载。运输方式由特斯拉物流公司决定。如有任何问题,请联系Logistic_Inbound@tesla.com。

5. Suppliers must execute shipments according to Tesla’s demand releases, which are transmitted by EDI (830 Forecast and 862 Firm Demand) or through the Tesla Supplier Portal.

供应商必须根据特斯拉的需求发布来执行发货,这些需求通过EDI(830预测和862确定需求)或通过特斯拉供应商门户网站传送。

- EDI:

Please contact your Planning contact and TeslaEDI@teslamotros.com for

setup and guidance.

请联系你的计划联系人和TeslaEDI@teslamotros.com,以获得设置和指导。

-Supplier Portal 供应商门户网站:

Pls contact your Tesla Planning contact and representative and SupplierPortal@teslamotors.com for access and guidance.

请联系你的特斯拉计划代表和SupplierPortal@teslamotors.com,以获取和指导。

6. Suppliers must submit an Advanced Ship Notice (ASN) for each production shipment to Tesla and follow the Shipment Labels requirement. This is required even in cases when the supplier is managing the shipment. Suppliers can submit an ASN in two ways:

供应商必须为每批运往特斯拉的生产货物提交一份提前发货通知(ASN),并遵守发货标签的要求。即使在供应商管理货物的情况下,也必须这样做。供应商可以通过两种方式提交ASN:

EDI

Suppliers choosing EDI 856 for ASN must generate their own shippinglabels up to Tesla specification and complete a verification process with

the Tesla EDI team. Please contact your Planning contact and

TeslaEDI@teslamotros.com for setup and guidance.

选择EDI 856的ASN的供应商必须自己生成符合特斯拉规格的运输标签,并完成与特斯拉EDI团队的验证过程。请联系您的计划联系人和

TeslaEDI@teslamotros.com,以获得设置和指导。

Supplier Portal 供应商门户网站

Suppliers choosing Portal must enter shipment data and print the labels from the Supplier Portal. Please contact your Planning contact and

SupplierPortal@teslamotors.com for access and guidance

选择门户网站的供应商必须在供应商门户网站上输入装运数据并打印标签。请联系您的计划联系人和SupplierPortal@teslamotors.com,以获得访问和指导。

7. Suppliers shipping to other vendors or receiving material from a vendor on Tesla’s behalf must complete the shipping and receiving process through the Tesla Supplier Portal only. Please reach out to your Purchasing contact for Tesla’s subcontract shipping and receiving procedures.

供应商向其他供应商发货或代表特斯拉从供应商处接收材料,必须只通过特斯拉供应商门户网站完成发货和接收程序。请与您的采购联系人联系,了解特斯拉的分包运输和接收程序。

5.6.5 Invoicing 开具发票

Tesla has implemented e-invoicing for direct material with purchase order numbers starting with 72, 74, or 77. Suppliers need to submit all invoices through one of the following three channels. Contact e invoicing@teslamotors.com for specifications and detailed instructions

特斯拉已对采购订单号以72、 74或77开头的直接材料实施电子发票。供应商需要通过以下三个渠道之一提交所有发票。请联系e-invoicing@teslamotors.com,了解规格和详细说明。

1. EDI,

2. CSV Upload CSV上传。

3. Shipment Flip in Tesla Supplier Portal.特斯拉供应商门户网站中的发货翻页。

5.6.6 Certificate of Compliance 合格证书

Suppliers may be requested to submit certificates of compliance, showing a record that all part/materials were processed in full compliance with all drawing specifications and/or technical provisions described in the Purchase Order. Suppliers should refer to BMS- 0000342 - Certificate of Compliance for full details.

供应商可能会被要求提交合规证书,以证明所有部件/材料的加工完全符合采购订单中描述的所有图纸规格和/或技术规定。供应商应参考BMS- 0000342 - 合格证的全部细节。

5.7 Regulatory Compliance 监管合规

Suppliers of Components may be required to provide evidence of compliance conformance outlined by international bodies in support of Tesla vehicle sales. Compliance to regulatory compliance is the responsibility of the supplier who will present to Tesla electronic copies of compliance certificates to the Supplier Portal.

组件供应商可能被要求提供国际机构概述的合规性证据,以支持特斯拉汽车销售。遵守法规是供应商的责任,他们将向特斯拉的供应商门户网站提交合规证书的电子副本。

5.7.1 Material Regulatory Compliance 材料监管合规

Tesla suppliers are required to adhere to international material compliance requirements in order to meet regional material and environmental regulations. This is a mandatory requirement for all suppliers who supply products or raw materials to Tesla; vendors who provide only non-material related services are exempted. Specific requirements may be found in BMS-0000408 - Material Compliance Reporting.

特斯拉供应商必须遵守国际材料合规要求,以满足地区材料和环境法规。这是对所有向特斯拉提供产品或原材料的供应商的强制性要求;只提供非材料相关服务的供应商则被豁免。具体要求可在BMS-0000408-材料合规报告中找到

5.8 Nonconforming Parts 不合格的零件

This section covers the procedures and disposal for nonconforming parts at the supplier manufacturing site and nonconforming parts sent to Tesla.本节涵盖了供应商生产现场的不合格零件和送往特斯拉的不合格零件的程序和处置。

1. If a nonconforming part is identified at the supplier manufacturing site, and has already been shipped to Tesla, immediate e-mail notification must be sent to the Tesla to intercept and quarantine the parts upon arrival. A Notice of Suspect Shipment / Deviation Request form must be submitted using Tesla’s format provided in BMS-0000259 - Supplier Quality Toolkit.

如果在供应商生产现场发现了不合格的零件,并且已经运到了特斯拉,必须立即向特斯拉发送电子邮件通知,以便在零件到达后进行拦截和检疫。必须使用BMS-0000259-供应商质量工具包中提供的特斯拉格式,提交一份可疑货 物通知/偏差请求表。

2. If a nonconforming part is identified at Tesla, the supplier will be notified via email and / or the Tesla SCAR Database.

如果在特斯拉发现不合格零件,将通过电子邮件和/或特斯拉SCAR数据库通知供应商。

3. When a nonconformance is discovered, the supplier is by default assumed responsible for the faults. Investigations shall be conducted by the supplier until the cause of the nonconformance has been identified and a plan proposed to prevent the problem from occurring again.

当发现不符合要求的情况时,供应商被默认为对故障负责。供应商应进行调查,直到找出不合格的原因,并提出防止问题再次发生的计划。

4. Tesla reserves the right to charge suppliers for costs incurred as a result of receiving nonconforming parts / material, in accordance with the charge back policy in the General Terms.

特斯拉保留向供应商收取因收到不合格的零件/材料而产生的费用的权利,这符合一般条款中的收费政策。

5.8.1 Deviation Approval偏差批准

In some cases, Tesla may approve parts which do not fully adhere to the specifications but that do not affect fit, function, material compliance requirements or safety, to be used “as is,”. To obtain approval for a deviation to ship such parts, the Notice of Suspect Shipment / Deviation Request form must be completed and submitted to Tesla. Approval from Tesla is required before supplying any nonconforming product under a Deviation Approval.

在某些情况下,特斯拉可能会批准不完全符合规格但不影响配合、功能、材料符合性要求或安全的部件, "按原样 "使用。为获得对此类零件发货的偏差批准,必须填写可疑发货通知/偏差请求表并提交给特斯拉。在根据偏差批准提供任何不符合要求的产品之前,必须得到特斯拉的批准。

5.8.2 SCAR - Supplier Corrective Action Request

供应商纠正措施请求

A SCAR will be issued to notify the supplier that Tesla has received a nonconforming part.When the SCAR is issued, the supplier will receive an automated e-mail notification. The supplier is required to respond and complete the supplier sections of the SCAR form on Tesla’s SCAR Database within the timeframe outlined below:

将发布SCAR,通知供应商特斯拉收到了一个不符合要求的零件。当SCAR发出后,供应商将收到一封自动的电子邮件通知。供应商需要在以下时间范围内回复并完成特斯拉SCAR数据库中SCAR表格的供应商部分:

1. Supplier Information 供应商信息

The supplier must provide a point of contact for the SCAR within 2 local business hours.

供应商必须在当地2个工作小时内提供一个SCAR的联络点。

2. Supplier Containment / Sorting 供应商遏制/分拣

The supplier must provide details on the immediate actions taken to contain all suspect and non-certified parts within 24 hours. Use Tesla’s Certified Shipment Tag as provided in BMS-0000259 - Supplier Quality Toolkit for identifying certified parts and complete the information on the tag.

供应商必须详细说明在24小时内为遏制所有可疑和非认证零件而采取的即时行动。使用BMS-0000259-供应商质量工具包中提供的特斯拉认证装运标签来识别认证部件,并完成标签上的信息。

3. Supplier Root Cause 供应商的根本原因

In-depth analysis of the reported problem shall be conducted to determine the true underlying cause(s) and / or reason for the discrepancy and reported to Tesla within 14 days. The supplier is assumed responsible until an acceptable resolution is found.

应深入分析报告的问题,以确定真正的根本原因和/或差异的原因,并在14天内向特斯拉报告。在找到可接受的解决方案之前,供应商应承担责任。

4. Supplier Countermeasure 供应商对策

- Irreversible, long-term action taken to ensure that the problem will not

recur. 采取不可逆的长期行动,以确保问题不再发生。

- Methods that may be used are mistake-proofing systems, process changes, or tool changes; depending on the change, the supplier may be request to re-acquire TQP approval.

可能使用的方法是防错系统、过程改变或工具改变;根据改变,供应

商可能被要求重新获得TQP批准。

- Permanent countermeasures must be implemented within 30 days》

必须在30天内实施长期反措施。

Supplier Sort Marks 供应商分类标记

“Sort Marks”, or “Part Certification Marks”, used as an indication that an inspection process has been performed, shall be applied and evident on the parts as directed by Tesla. Permission and direction from Tesla as to the shape, location, and color of the mark is required prior to the application of any marks. Tesla approved acceptable marking provides visible verification that a sorting/inspection process has occurred without impact to fit, form, function or cosmetic concerns. This requirement must also be passed on to all appropriate sub-suppliers.

"分类标记 "或 "部件认证标记",作为已执行检查程序的指示,应按照特斯拉的指示在部件上应用并显示出来。在使用任何标记之前,必须得到特斯拉对标记的形状、位置和颜色的许可和指导。特斯拉批准的可接受的标记提供了可见的验证,证明分类/检查过程已经发生,而不影响配合、形式、功能或外观问题。这一要求也必须转达给所有适当的次级供应商。

Return / Scrap Material Authorization 退货/报废材料授权

The supplier must provide an RMA # to reference the authorization to return or scrap nonconforming part(s) for credit within 7 days from the first notification of nonconforming parts. If the nonconforming part(s) are to be returned to the supplier, the supplier must provide Tesla a shipping account to use and / or arrange pick-up at Tesla.

供应商必须提供一个RMA号码,以便在第一次收到不合格部件的通知后7天内,参考不合格部件的退货或报废授权,以获得信贷。如果不合格的零件要退回给供应商,供应商必须向特斯拉提供一个运输账户,以便使用和/或安排到特斯拉取货。

5.8.3 Product Containment / Controlled Shipping

产品遏制 /受控发运

Controlled Shipping Level 1 一级受控发运

Controlled Shipping Level 1 is a demand by Tesla that a supplier put in place a redundant inspection process at the supplying location to sort for a specified non-conformance, implement a root-cause problem solving process, and isolate Tesla from the receipt of nonconforming parts/material. The redundant inspection is in addition to normal controls, and is enacted by the supplier’s employees. If placed on Level Containment by Tesla, the supplier will do the following:

一级受控发运是特斯拉要求供应商在供应地点实施额外检验程序,对特定的不合格品进行挑选,实施基于根本原因的问题解决程序,并防止特斯拉接受不合格零件/材料。额外检验是对正常控制的补充,并由供应商的员工实施。如果被特斯拉置于1级遏制状态,供应商将采取以下措施:

- Submission of a Level 1 containment plan and/or corrective action plan to Tesla.

向特斯拉提交一级遏制计划和/或纠正措施计划。

- Evidence based on data from the controlled shipping area that the normal production process is free of all non-conformances for a minimum of 20 working days after the start of mass production or implementation of permanent corrective action.

根据受控运输区的数据,证明正常生产过程在开始批量生产或实施长期纠正措施后,至少20个工作日内没有任何不符合要求的情况。

Level 1 Containment may be elevated to Controlled Shipping Level 2 and/or New Business Hold if zero defects and/or permanent corrective action is not achieved.

如果不能实现零缺陷和/或长期纠正措施,1级遏制可能会被提升为2级受控发运和/或新业务暂停。

Controlled Shipping Level 2 二级受控发运

Controlled Shipping Level 2 is a Tesla requirement to a supplier to put in place a 3rd party redundant inspection process to sort for a specific nonconformance, while maintaining Controlled Shipping Level 1 inspections, and implementing a root-cause problem solving process. The data obtained from the 3rd party redundant inspection process as well as process audits are critical as both a measure of the effectiveness of the secondary

inspection process and the corrective actions taken to eliminate the initial

nonconformance

二级受控发运是特斯拉对供应商提出的要求,即在保持一级受控发运检查的同时,建立第三方额外检验程序,对特定的不合格情况进行挑选,并实施根本原因问题解决程序。从第三方额外检验过程以及过程审核中获得的数据是至关重要的,它既是衡量二级检验过程的有效性,也是为消除最初的不合格所采取的纠正措施。

Controlled Shipping Level 2 will be initiated for one or more of the following reasons:

二级受控发运将因以下一个或多个原因而启动:

- Repeat Non-Conformances as addressed by Tesla’s SCAR Database.

特斯拉的SCAR数据库所处理的重复不合格品。

- Repeat failure to submit compliance data that accurately reflects the physical component.

屡次未能提交准确反映物理成分的合规数据。

- Supplier’s current controls not sufficient to ensure conformance to requirements.

供应商的现有控制措施不足以确保符合要求。

Controlled Shipping Level 1 failures.

一级发运受控的失败。

- Major Production Line Disruptions.

主要的生产线中断。

- Quality Problem in the field (Warranty).

现场的质量问题(保修)。

Level 2 Containment will be initiated with a formal meeting between Tesla, the third-party and the supplier to establish all containment criteria. Exit from Controlled Shipping Level 2 will be based on data that the normal production process is free of all non-conformances for a minimum of 20 working days after the implementation of permanent corrective action.

二级遏制将由特斯拉、第三方和供应商之间的正式会议启动,以确定所有遏制标准 。退出二级受控发运将基于以下数据:在实施长期纠正措施后,正常生产过程中至少有20个工作日没有出现任何不符合要求的情况。

Level 2 Containment may cause the supplier to be subjected to a new business hold if timely permanent corrective action is not achieved.

如果没有及时采取长期纠正措施,二级遏制可能会使供应商受到新的业务暂停。

The Supplier may submit a written request to Tesla, after the minimum 20 working days, to be removed from any containment level. This request must provide evidence that all the criteria of the containment have been met. Tesla will remove the supplier containment status after verification of the effectiveness of implemented actions.

供应商可在至少20个工作日后向特斯拉提交书面申请,要求从任何遏制级别中移除 。该请求必须提供证据,证明该遏制等级的所有标准已经得到满足。特斯拉将在核 实所实施行动的有效性后取消供应商的遏制状态。

5.8.4 Warranty 售后

1.Tesla will provide all relevant warranty claim information associated with warranty return part(s) and provide a sample of warranty return part(s) when available. Supplier may also request part(s) and/or data from Tesla.

特斯拉将提供与售后退货零件相关的所有相关售后索赔信息,并在有条件时

提供售后退货零件的样本。供应商也可以向特斯拉索取零件和/或数据。

2.Suppliers are required to analyze all warranty return parts and:

供应商需要分析所有保修期内退回的零件和:

- Report the investigation results to Tesla.

向特斯拉报告调查的结果。

- Propose/implement countermeasures.

提出/实施措施。

- Confirm effectiveness of the countermeasure.

确认措施的有效性。

3.Supplier is responsible for all costs incurred by Tesla resulting from the delivery of non-conforming products and in accordance with the General Terms.

供应商负责支付特斯拉因交付不合格产品而产生的所有费用,并按照一般条 款的规定负责。

4.In the event where analysis results are inconclusive (NTF or “No Trouble Found”) after 30 days or within the timeframe set by Tesla, the supplier and Tesla will jointly analyze the cause of failure and cost ownership.

如果30天后或在特斯拉规定的时间范围内,分析结果没有结果(NTF或 "未发现故障"),供应商和特斯拉将共同分析故障原因和成本所有权。

5.A warranty recovery contact at Tesla will send a warranty claim based on the results of the analysis. The supplier will promptly send an agreement in writing. If the Supplier does not respond within 14 days from when the claim is made, the supplier will be deemed to have accepted the charges.

特斯拉的保修恢复联系人将根据分析结果发送一份售后索赔。供应商将及时 发送一份书面协议。如果供应商在索赔时起的14天内没有回应,供应商将被视为已接受收费。

6.If additional time is required for the supplier to appeal for charges, the supplier shall submit a written communication to request more time or a meeting to discuss the rationale for the appeal.

如果供应商需要更多的时间为收费提出上诉,供应商应提交一份书面函件, 要求更多的时间或开会讨论上诉的理由。

7.Field quality performance and cost recovery concerns will be a significant factor in new product sourcing decisions.

对现场质量性能和成本回收的关注将成为新产品采购决策中的一个重要因素。

5.9 HVPT- High Volume Production Trial 大批量生产实验

1.The Tesla format provided in BMS-0000259 - Supplier Quality Toolkit must be used to evaluate the HVPT.

必须使用BMS-0000259-供应商质量工具包中提供的Tesla格式来评估HVPT。

2.A HVPT is required for each new TQP and PCR.

每个新的TQP和PCR都需要一个HVPT。

3.The pre-launch control plan must be followed during the production trial run.

在生产试运行期间,必须遵循启动前的控制计划。

4.The scope and reporting of the HVPT and associated studies (refer Sections 6.4.3 and 6.4.4) shall be performed according to their individual requirements.

HVPT 的范围和报告以及相关研究(参考第 6.4.3 和 6.4.4 节)应根据各自的 要求进行。

5.Concerns identified during the trial run must be added to the Problem FollowSheet (refer Section 6.5.4).

在试运行期间发现的问题必须添加到问题跟踪表中(参考第6.5.4节)。

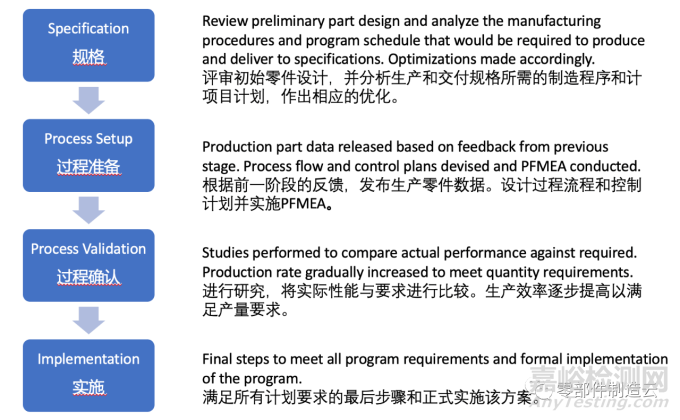

Section 6 TQP-Tesla Qualification Process

第六节 特斯拉资格认证程序

6.1 Overview 总览

A successful launch at mass production is achieved through coordination and study of production trials, sample evaluation, part fitment and assembly trials. Tesla employs the preparation stages below as incremental steps towards mass production. By default, all aspects of each stage must be completed by the supplier unless directed by a Tesla representative. Other tasks may also be added by a Tesla representative.

通过协调和研究生产试验、样品评估、零件装配和组装试验,成功地启动了大规模

生产。特斯拉采用以下准备阶段作为实现大规模生产的渐进步骤。默认情况下,每

每个阶段的所有方面都必须由供应商完成,除非有特斯拉代表的指示。其他任务也可

也由特斯拉代表添加。

6.2 Specification 规格

6.2.1 Program Schedule 项目时间表

The Program Schedule is the overall project plan for supplier quality activities, from drawing issuance through TQP approval, to initial shipments of mass production parts.

项目时间表是供应商质量活动的总体项目计划,从图纸发布到TQP批准,再到批量生产零件的初始出货。

1.The initial schedule is to be drafted with RFQ submission and finalized shortly after if awarded the business. It shall, at a minimum, define timing for the following:

最初的时间表将在提交RFQ时起草,如果获得业务,则在不久后定稿。它至 少应确定以下事项的时间:

- Tesla Master Schedule – Prototype, Assembly trials, Start of Production.

特斯拉主时间表 - 原型样件,装配试验,开始生产。

- Supplier Master Schedule – Prototype, TQP trials, Start of Production.

供应商主时间表--原型样件、TQP试验、开始生产。

- Production Level – Process and test equipment.

生产水平 - 加工和测试设备。

- Evaluations – Part evaluations to be done during trials.

评估--在试验期间要进行的零件评价

- Testing – Plan for testing parts to Drawing and Inspection Standard.

测试 - 按照图纸和检验标准测试零件的计划

- TQP documentation – Timing for each TQP task.

TQP文件 - 每个TQP任务的时间安排

2.If awarded business, future schedule planning and changes shall be performedthrough the Supplier Portal.

如果获得业务,未来的日程规划和变更应通过供应商门户网站进行

3.A schedule resubmission is required for each new TQP Approval or PCR.每次新的TQP批准或PCR都需要重新提交时间表。

4.The schedule shall be reviewed regularly in intervals designated by Tesla.该时间表应在特斯拉指定的时间间隔内定期评审。

6.2.2 Inspection Standard 检验标准

The Inspection Standard is a document that supports a part’s associated drawing(s) and details significant part characteristics, their acceptance criteria and the method and frequency by which they must be monitored and controlled by the supplier.

检验标准是一份支持零件相关图纸的文件,详细说明了重要的零件特性、验收标准以及供应商必须对其进行监测和控制的方法和频率。

1.Suppliers are required to make Inspection Standards for all parts. Tesla retains the official, signed document.

供应商需要对所有零部件做出检验标准。特斯拉保留正式的、签署的文件。

2.The Tesla format provided in BMS-0000259 - Supplier Quality Toolkit must be used.

必须使用BMS-0000259-供应商质量工具包中提供的特斯拉格式。

3.The part Inspection Standard, at a minimum, must define the following part characteristics: 零件检验标准,至少必须定义以下零件特征:

- Datum Structure. Datum结构

- Dimension and Tolerance. 尺寸和公差

- Performance. 性能

- Weight. 重量

- Material.材料

- Appearance standards.外观标准

- Function.功能

- Color and/or Grain (if applicable).颜色和/或纹理 (如适用)

- Critical Items.关键项目

- Identification and Traceability Methods.标识和可追溯性方法。

4.The Inspection Standard must consider and include inspection related criteria as indicated on the Control Plans, PFMEA studies, etc., and the frequency of inspection must be developed based upon process capabilities.

检验标准必须考虑并包括控制计划、PFMEA等所指出的与检查有关的标准,而且检查的频率必须根据过程能力来制定。

5.The approved Inspection Standard criteria, subject to revision, must be followed for the life of the part without exception.

经批准的检验标准,可进行修订在零件的使用寿命内必须遵守,没有例外。

6.Drawing requirements not specifically stated on the part Inspection Standard must be revalidated annually at a minimum.

在零件检验标准中没有特别说明的图纸要求必须至少每年重新验证一次。

7.The supplier must initiate revisions for all Engineering Change Orders.

供应商必须启动所有工程变更单的修订工作。

8.The supplier must submit all Inspection Standard revisions to Tesla.

供应商必须向特斯拉提交所有检验标准的修订。

6.2.3 Measurements Systems Analysis (MSA) for Equipment Proposal 设备提案的测量系统分析(MSA)

1.An MSA shall be conducted on all components that meet any or all of the following conditions: 对符合以下任何或所有条件的所有部件都应进行MSA

- Require a capability analysis be conducted.

要求进行能力分析。

- Contain critical or special characteristics.

含有关键或特殊特性。

- Require on-going production monitoring.

要求持续的生产监测。

- As requested by Tesla.

按照特斯拉的要求

2.The supplier shall submit to Tesla a proposal for all tools, gauges, fixtures and other equipment required to produce parts to Tesla’s specifications and to meet the MSA requirements.

供应商应向特斯拉提交所有工具、量具、夹具和其他设备的建议书,以便按 照特斯拉的规格生产零件并满足MSA要求。

3.The supplier shall ensure all proposed tools, gauges, fixtures and/or equipment meet the requirements set in Section 5.4.

供应商应确保所有提议的工具、量具、夹具和/或设备符合第5.4节规定的要 求。

4.No tools, gauges, fixtures or equipment may be purchased without written authorization and funding approval from Tesla.

没有特斯拉的书面授权和资金批准,不得购买工具、量具、夹具或设备。

6.2.4 Control Plan (Prototype) 控制计划(原型样件)

1.The Prototype Control Plan shall be created and submitted to Tesla for review, and cover all aspects detailed in Section 5.3.

原型控制计划应创建并提交给特斯拉评审,并涵盖第5.3节详述的所有方面

2.The scope of the plan should extend to cover either the production of prototype parts for Tesla or any production using tooling, equipment, or processes that are not mass production intent.

计划的范围应扩大到包括为特斯拉生产原型零件或任何使用非大规模生产意图的工具、设备或工艺的生产。

3.Control Plans for prototype part production must consider factors such as the production methods, production quantities, and any added validation requirements associated with the intended use of the prototype parts.

原型零件生产的控制计划必须考虑诸如生产方法、生产数量以及与原型零件的预期用途有关的任何附加验证要求等因素。

4.Control Plans for tooling, equipment, and processes that are not mass production intent must consider factors that could result from the potential failure modes of the alternative production methods.

非大规模生产意图的工具、设备和工艺的控制计划必须考虑替代生产方法 的潜在故障模式可能导致的因素。

6.2.5 2D Drawing GD&T 平面图纸形位公差

Suppliers providing component designs are responsible for providing GD&T data on all drawings, adhering to the following requirements:

提供零件设计的供应商负责在所有图纸上提供GD&T数据,遵守以下要求:

1.Drawings must follow the standards and requirements outlined in BMS-0000023 - Drawing Block and Notes Standard, in addition to the requirements listed here.

图纸必须遵循BMS-0000023中列出的标准和要求。 - 除了这里列出的要求外,还有图块和注释标准。

2.Drawings and specifications should include engineering specification tests, product validation test requirements, and must be documented in time to support pre-launch Control Plan development.

图纸和规格应包括工程规格测试、产品验证测试要求,并且必须及时记录下 来,以支持量产前控制计划的制定。

3.Lot control and traceability requirements must be detailed on the drawings.

批量控制和可追溯性要求必须在图纸上详细说明。

4.Visual acceptance standards should define all potential visual concerns that may occur on the parts (i.e. grain, gloss, color, surface imperfections etc.) Visual standards should be developed jointly between the Tesla and the supplier, and should be approved prior to design release (e.g. A, B, and C surfaces to be defined and aligned to Tesla requirements).

目视验收标准应定义零件上可能出现的所有潜在的视觉问题(即纹理、光泽 、颜色、表面缺陷等)。目视标准应在特斯拉和供应商之间共同制定,并在设计发布前得到批准 (例如,A、B、C面要定义并与特斯拉的要求一致)。

5.Critical characteristics must be indicated on drawings using the symbols defined in Section 7.3 of this document and within BMS-0000023 - Drawing Block and Notes Standard. In the event of conflicting information, BMS-0000023 - Drawing Block and Notes Standard shall take precedence.

关键特性必须使用本文件第7.3节和BMS-0000023-图块和注释标准中定义的 符号在图纸上注明。如果信息有冲突,应以BMS-0000023-图块和注释标准为准。

6.2.6 Design for Manufacturing(DFM) Complete

制造设计(DFM)完成

Suppliers providing component designs are responsible for conduction a DFM analysis to ensure part design optimization. The following points are required:

提供零件设计的供应商负责进行DFM分析,以确保零件设计优化。需要注意以下几点

1. Suppliers shall complete the Team Feasibility form in BMS-0000259 - Supplier Quality Toolkit and submit to their Tesla representative.

供应商应填写BMS-0000259-供应商质量工具包中的团队可行性表格,并提 交给其特斯拉代表。

2. Suppliers shall provide evidence of manufacturability and assembly analysis through CAE simulation or otherwise.

供应商应提供通过CAE模拟或其他方式进行可制造性和装配分析的证据。

3. Suppliers should contact their appropriate Tesla representative for additional requirements.

供应商应与他们相应的特斯拉代表联系,以了解更多的要求。

6.3 Process Setup 过程准备

6.3.1 Process Flow Chart 过程流程图

1.A Process Flow Chart shall be drafted to detail each and every step in the supplier’s manufacturing process.

应起草一份过程流程图,详细说明供应商生产过程中的每一个步骤。

2.Any expected re-work processes must be shown in the Process Flow Chart.

任何预期的返工过程必须显示在流程图中。

3.The format in BMS-0000259 - Supplier Quality Toolkit may be used.

可以使用BMS-0000259-供应商质量工具包中的格式。

6.3.2 PFMEA - Process Failure Mode and Effects Analysis

过程失效模式及后果分析

Suppliers are required to complete a PFMEA and update it with improvements made during the trial phases, as a result of process changes, or changes due to corrective actions. The supplier must use cross functional approach to complete the PFMEA.

供应商必须完成PFMEA,并根据试验阶段的改进、过程变化或纠正措施带来的变化进行更新。供应商必须使用跨职能的方法来完成PFMEA。

1.Follow the industry standard AIAG - Failure Mode & Effects Analysis (FMEA) Reference Manual.

遵循行业标准AIAG - 失效模式与后果分析(FMEA)参考手册。

2.Design Failure Mode Effects Analysis (DFMEA) (if applicable) and Process Failure Mode Effects Analysis (PFMEA) must include reviews of both the equipment and the process. These activities should be completed prior to drawing release, tooling/process design, Process Control Plan, Inspection Standard, and Inspection Plan development.

设计失效模式影响分析(DFMEA)(如果适用)和过程失效模式影响分析( PFMEA)必须包括对设备和工艺的审查。这些活动应在图纸发布、工具/工 艺设计、过程控制计划、检验标准和检验计划制定之前完成。

3.Significant product failure items identifed through DFMEA development that are not corrected with a design change must be indicated on the PFMEA and Control Plan documents, with sufficient inspection and prevention / detection capabilities to prevent non-conformances.

通过DFMEA开发确定的重大产品失效项目,如果没有通过设计变更来纠正, 必须在PFMEA和控制计划文件中指出,要有足够的检查和预防/检测能力来防止不合格品。

4.Equipment / Process capability deficiencies identified based on the results from analytical studies such as PFMEA, etc., must be represented in the inspection plans and associated documents (ie: Process Control Plan, Inspection Standard, etc.) as required with 100% inspection criteria to ensure consistent achievement of quality requirements.

根据PFMEA等分析研究的结果确定的设备/工艺能力缺陷,必须在检验计划和相关文件(即:工艺控制计划、检验标准等)中体现出来,要求100%的检验标准,以确保质量要求的一致实现。

5.Sub-suppliers that provide materials or components that impact the Tier 1 part safety or regulatory requirements must develop, submit, and gain approval from the Tier 1 Supplier of a specific quality control plan, that assures conformance of their material, component or assembly. In the case of direct supply, the responsible Tesla representative has approval responsibility.

提供影响一级零件安全或监管要求的材料或零件的次级供应商必须制定、提交并获得一级供应商对具体质量控制计划的批准,以确保其材料、零件或组件的一致性。在直接供应的情况下,负责的特斯拉代表有批准责任。

6.The supplier must ensure that documented systems are in place at all sub- suppliers to control traceability and confirm specification compliance for all critical components including raw materials, parts, and assemblies.

供应商必须确保所有次级供应商都有记录在案的系统,以控制可追溯性,并确认所有关键部件(包括原材料、零部件和组件)符合规格。

7.Safety, regulatory and FMVSS related processes must be continually monitored and controlled in regards to capability, utilizing industry accepted methods of statistical control. Refer to Section

6.4.4 for Capability requirements of specialcharacteristics.

安全、监管和FMVSS相关的过程必须在能力方面进行持续的监测和控制,利用行业公认的方法统计控制。关于特殊特性的能力要求,请参考第6.4.4节。

8.Specific plans and methods must be developed and utilized to ensure full traceability to include material lot identification, date, shift, assembly process, and delivery, verification of repair, and containment assurance.

必须制定和使用具体的计划和方法,以确保全面的可追溯性,包括材料批次标识、日期、班次、装配过程和交付、维修验证和密封保证。

9.The final PFMEA shall be submitted for TQP approval.

最终的PFMEA应提交给TQP批准。

6.3.3 Control Plan (Production) 控制计划(批量生产)

1.The Production Control Plan shall be created and submitted to Tesla for review, and cover all aspects detailed in Section 5.3.

生产控制计划应建立并提交给特斯拉审查,并涵盖第5.3节中详述的所有方面。

2.The scope of the Production Control Plan should only cover parts produced during mass production.

生产控制计划的范围应只包括大规模生产过程中生产的零件。

6.3.4 Measurement Systems Analysis (MSA) for Equipment Acceptance 设备验收的测量系统分析(MSA)

1.Once written authorization and funding approval has been received for a proposed tool, fixture, gauge and/or equipment, the supplier shall create an Instruction Manual(s) covering its correct use to meet Tesla’s requirements. Purchased tool, fixture, gauge and/or equipment shall be qualified for fitness of use (eg: certification).

一旦收到拟议的工具、夹具、量具和/或设备的书面授权和资金批准,供应商应编制一份涵盖其正确使用的指导手册以满足特斯拉的要求。购买的工具 、夹具、量具和/或设备应符合使用条件(例如:认证)。

2.All Instruction Manuals shall be submitted to Tesla for approval and should not be used until approved. The format in BMS-0000259 - Supplier Quality Toolkit may be used.

所有指导手册应提交给特斯拉批准,在获得批准之前不应使用。可以使用 BMS-0000259-供应商质量工具包中的格式。

6.4 Process Validation 过程确认

6.4.1 Measurement Systems Analysis (MSA) for Equipment Validation 用于设备确认的测量系统分析(MSA)

1.An MSA shall be conducted as per TS-0003413 - Measurement Systems Analysis Standard using inspection personnel with conditions as similar to the mass production operations as possible at the supplier site.

MSA应按照TS-0003413-测量系统分析标准进行,使用检查人员,其条件尽可能与供应商现场的大规模生产操作相似。

2.The results of the MSA shall be submitted to Tesla as detailed in the referenced Tesla standards listed in Section 5.4.

MSA的结果应按照第5.4节所列的参考特斯拉标准中的详细规定提交给特斯 拉。

6.4.2 Validation Testing 确认性测试

1.Validation tests will be conducted as per the Inspection Standard and an analysis of the results submitted to the portal. All tests will be conducted on parts/processes representative of final production intent pedigree or as agreed by Tesla.

确认测试将按照检验标准进行,并向门户网站提交结果分析。所有测试都将在代表最终生产意图的零件/过程上进行,或经特斯拉同意。

6.4.3 Capacity Study 产能研究

A Capacity Study shall be prepared for every process/line used by the supplier. The study should be included in the TQP and PCR submissions as well as be updated for all process improvements and changes. The Capacity Study will be used by Tesla to confirm the expected capacity for a given part.

应为供应商使用的每道工序/生产线准备一份能力研究报告。该研究应包括在提交 的TQP和PCR中,并为所有过程改进和变化进行更新。特斯拉将使用产能研究报告来确认某一特定零件的预期能力。

1.The Tesla format provided in BMS-0000259 - Supplier Quality Toolkit or on the Supplier Portal may be used.

可以使用BMS-0000259-供应商质量工具包中提供的特斯拉格式或供应商门户 网站上的格式。

2.A study shall be conducted for each line, machine, tool, etc. used and whenever a line, machine, tool, etc. is added, changed or removed.

对每一条使用的生产线、机器、工具等,以及每当增加、改变或移除生产线机器、工具等,都应进行研究。

3.The number of parts used to evaluate the study shall be determined by Tesla.

用于评估研究的部分数量应由特斯拉决定。

4.Run at Rate (R@R) studies shall be conducted to confirm that production capacity is correct to the supplier’s original planned capacity and capability.

应进节拍生产(R@R)研究,以确认生产能力与供应商的原计划产能和能力是正确的。

5.The study shall include the actual measured takt time for each operation.

该研究应包括每项操作的实际测量节拍时间。

6.The study shall follow the steps outlined in the Process Flow chart. If more than one operation is performed at a given station, the operations should be separate line items on the Capacity Study.

该研究应遵循过程流程图中描述的步骤。如果在一个给定的工位进行一个以上的操作,这些操作应在能力研究报告中作为单独的项目。

7.Process steps that do not meet Tesla’s demand forecast, for current or future volumes, must be added to the Problem Follow Sheet (PFS) and tracked for improvement.

不符合特斯拉对当前或未来数量的需求预测的流程步骤,必须添加到问题跟 踪表(PFS)中,并跟踪改进。

6.4.4 Capability Study 能力研究

1.Capability data (Ppk and Cpk) must be submitted at each trial up to, and including, the initial shipment for SOP. If a trial requires more than one shipment of parts, capability data will not be necessary after the initial shipment, provided the parts were manufactured in the same lot as the initial shipment.

能力数据(Ppk和Cpk)必须在每次试验中提交,直到(包括)首次发运的批量生产件 。如果一项试验需要一批以上的零件,那么在首次发运后就不需要提交能力数据,只要这些零件与首次发运的零件是同一批生产的。

2.Capability demonstrations, consisting of a minimum 30 part study, or an amount defined in the Tesla approved Inspection Standard, must be conducted per line, machine, tool, etc. or whenever a line, machine, tool, etc. is added, changed or removed.

每条生产线、机器、工具等或每当生产线、机器、工具等被添加、改变或移除时,都必须进行能力论证,包括至少30个零件的研究,或特斯拉批准的检验标准中规定的数量。

3.Cpk / Ppk data is required on all critical characteristics as designated by Tesla.

特斯拉指定的所有关键特性都需要Cpk / Ppk数据。

- All characteristics for safety, regulatory, and FMVSS requirements must have a Cpk and Ppk ≥ 1.67. All other special characteristics with Cpk or Ppk < 1.33 will not be accepted without 100% inspection.

所有用于安全、法规和FMVSS要求的特性必须有Cpk和Ppk≥1.67。所有其他特殊特性的Cpk或Ppk< 1.33如果没有100%的检查,将不被接受。

- Ppk / Cpk requirements may be established for additional specific part characteristics that significantly affect performance, fit, function, installation workability, or other identified FMEA items.

Ppk/Cpk可能要求针对,对性能、配合、功能、安装可操作性或其他已确定的FMEA项目有重大影响的其他特定零件特性而制定。

- The Inspection Standard will be used to define additional characteristics requiring a capability analysis.

检验标准将被用来定义需要进行能力分析的其他特性。

4.Cpk / Ppk data should be submitted on the Sample Data Sheet (SDS), or as directed by Tesla, from samples taken throughout each build. Samples must be taken from each die, cassette, line, cavity, etc. used in production.

Cpk/Ppk 数据应在样品数据表(SDS)上提交,或按照特斯拉的指示,从整个生产过程中抽取样品。必须从生产中使用的每个模具、料盒、生产线、空腔等处取样。

5.Continuous long term Ppk verification must be carried out for every critical characteristic, with acquired data maintained and utilized for continuous improvement. Tesla may request data submission at any time.

必须对每个关键特性进行持续的长期Ppk验证,并保持和利用获得的数据进行持续改进。特斯拉可在任何时候要求提交数据。

6.Inspection frequencies must be in conjunction with Cpk results. Depending on machine or process capabilities, the inspection requirements may increase or decrease. Any changes to the inspection frequency must be approved by Tesla through a modification of the Inspection Standard.

检查频率必须与Cpk结果相结合。根据机器或工艺能力的不同,检查要求可能会增加或减少。检查频率的任何变化必须通过修改检查标准得到特斯拉的批准。

7.Cpk / Ppk Inspection Sampling / Guidelines:

Cpk / Ppk检验取样/指南

|

Action Necessary |

Cpk |

Ppk |

|

Accept Product. Continue to reduce process variation. |

≥ 1.67 |

≥ 1.33 |

|