您当前的位置:检测资讯 > 科研开发

嘉峪检测网 2022-10-20 21:21

生物可降解聚氨酯因为其良好的生物相容性,可降解性,以及优异的力学性能 (柔软且有弹性)而被广泛应用于软组织修复。本篇综述从生物可降解热塑性聚氨酯的化学结构, 理化性质,功能性聚氨酯,以及其在组织再生修复中的实际应用作了一个综合阐述, 并指出了新型聚氨酯的研究和应用方向。

01研究内容简介

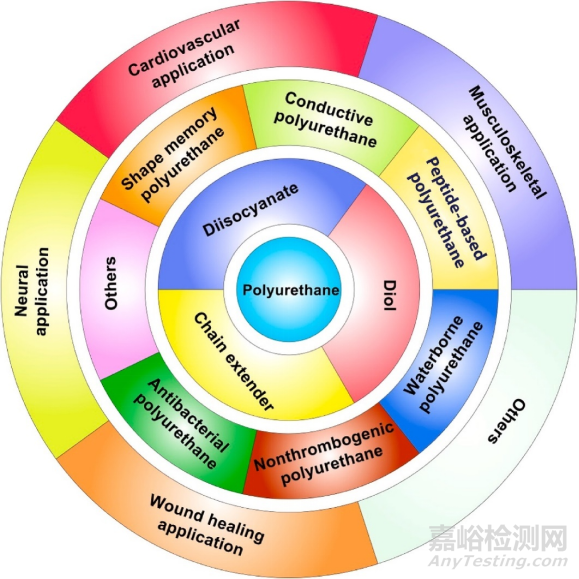

聚氨酯在生物医学领域的应用最早可以追溯到1960年代:一种用于心血管修复的 不可降解的聚氨酯。随后为了满足组织再生修复的需求,可降解型聚氨酯预1990年代开始进入人们的视野。生物可降解型聚氨酯具有良好的力学强度,柔软度,和弹性,使其成为软组织修复的理想材料。此外,热塑性聚氨酯拥有良好的可加工性,可以被加工成各种形状,使其更广泛的应用于组织修复。通常生物可降解型热塑性聚氨酯由三元结构组成:二异氰酸酯,可降解二元醇,和小分子扩链剂。调节这个三元结构的组成成分,可以赋予聚氨酯多样的理化性能和功能性, 进而适用于不同组织修复和再生 (图1)。

Fig. 1. Biodegradable polyurethanes: chemistry, functionalization, and tissue repair applications.

一、生物可降解型热塑性聚氨酯合成

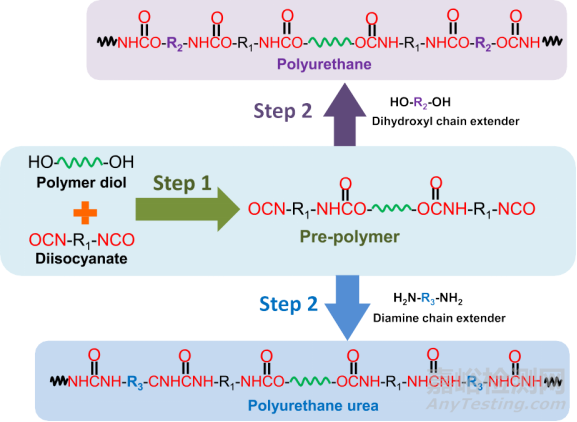

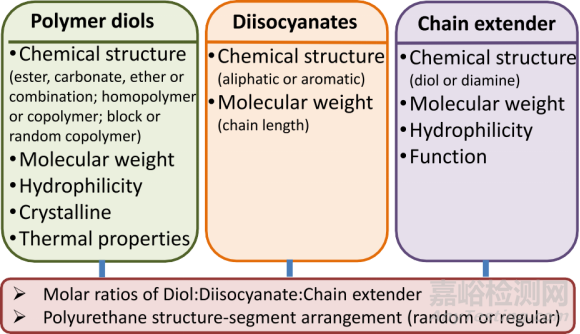

热塑性聚氨酯可以通过一步或者两步法制成。其中,两步法因为能够更好的控制其链段结构而得到更为广泛的应用 (图2)。如前所述,调节聚氨酯链段的三元结构成分可以得到不同的理化性质, 赋予其不同的功能性。比如使用聚酯或者聚酰胺之类的生物可降解多元醇作为软段可以确保聚氨酯具有生物可降解性。亦或者增加软段的链段长度或者使用无定形态聚合物作为软段可以降低聚氨酯的模量。扩链剂通常是小分子量的二醇或者是二胺,这样有助于聚氨酯硬段的有序排列。而二胺和异氰酸酯键形成的聚氨酯脲由于更多的氢键结合,会比二醇和异氰酸酯键形成的聚氨酯具有更强的力学性质。三元结构对于所形成的聚氨酯的理化性能的影响如图3所示。

Fig. 2. Typical synthesis routine of biodegradable polyurethane and polyurethane urea via a two-step method.

Fig. 3. List of component parameters that affect mechanical properties and degradation of biodegradable polyurethanes.

二、功能性生物可降解型热塑性聚氨酯

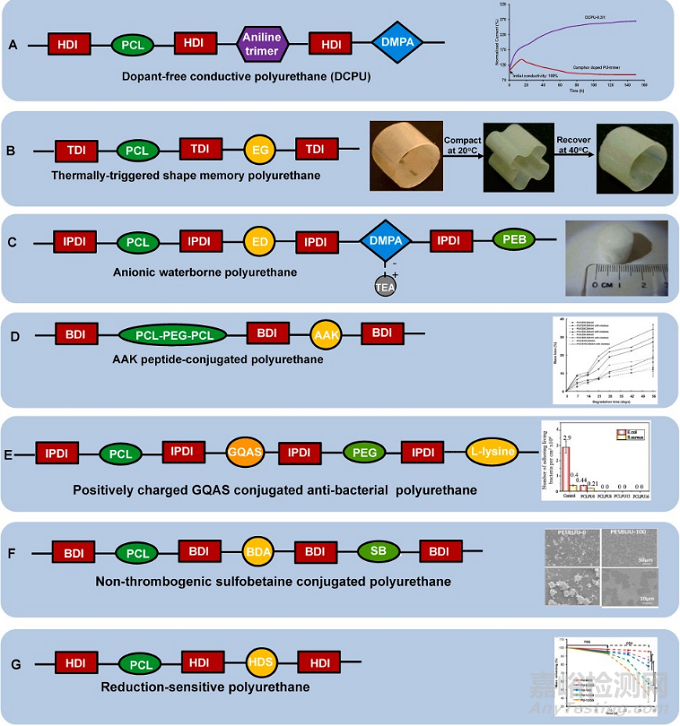

如前所述,通过调节展聚氨酯的三元结构成分,可以赋予其不同的功能性。比如,本文作者的课题组曾用苯胺三聚体作为扩链剂合成了具有导电性能的生物可降解聚氨酯,可以用于电信号响应的组织,如肌肉,神经,皮肤等组织的修复。此外,本课题组还曾经将二硫键引入聚氨酯链段中,使得聚氨酯具有还原敏感性, 可以用于还原敏感型药物载体制备以及降解可控型生物支架的制备。除此之外,还有很多其他功能型的聚氨酯,比如形状记忆型聚氨酯,水性聚氨酯,抗菌、抗凝血聚氨酯,详情如图4所示。

Fig. 4. Functional biodegradable polyurethane design.(A) Dopant-free conductive polyurethane. Structural design (left); Electrical stability (right): Relationship between electrical current and incubation time in the electrical stability test of DCPU-0.3/1 film in cell culture medium. Camphor doped PU-trimer film was used as a control. Reprinted with permission from [87]. Copyright 2016 Springer Nature. (B) Thermally triggered shape-memory polyurethane. Structural design (left); Shape memory behavior (right): Polyurethane cylinder was compacted into a flower shape at 40 ◦C and then cooled to room temperature immediately, and it returned to the original shape when immersed in 40 ◦C water. Adapted with permission from [109]. Copyright 2005 American Chemical Society. (C) Anionic waterborne poly- urethane. Structural design (left); Porous polyurethane sponge fabricated from polyurethane/water dispersion via freeze-drying (right). Reproduced with permission from [122]. Copyright 2014 Elsevier B.V. (D) AAKpeptide conjugated polyurethane. Structural design (left); Polyurethane enzymatic degradation manipulation by introducing elastase sensitive AAK sequence and varying the feeding ratio of polyether/polyester (PEG/PCL) in the soft segment (right). Reprinted with permission from [67]. Copyright 2005 American Chemical Society. (E) Positively charged GQAS conjugated anti-bacterial polyurethane. Structural design (left); Antibacterial activities (right): live bacteria attached on surfaces with and without GQAS and PEG. No live E. coli or S. aureus cells detected on all surfaces of the polyurethanes containing different GQASs compared with the PCLPU0 without GQAS, indicating the antibacterial property of GQAS. Reprinted with the permission from [167]. Copyright 2017 Royal Society of Chemistry. (F) Non-thrombogenic polyurethane. Structural design (left); Ovine blood platelet deposition on polyurethane films observed by scanning electron microscopy after blood contact for 2 h (right): PSBUU-0 was control group without SB content which had relatively high platelet deposition, while PSBUU-100 contained the highest SB content showing sparse platelet deposition. Reprinted with the permission from [176]. Copyright 2014 American Chemical Society. (G) Reduction sensitive polyurethane. Structural design (left); Electrospun polyurethane scaffold controllable degradation (right): Scaffolds were immersed in PBS for 14 d and then in 10 mM GSH for another 14 d, where the scaffold degradation rate increased obviously after transferring from PBS to GSH solution. * represents significantly different groups (p < 0.05). Reprinted with the permission from [31]. Copyright 2015 American Chemical Society.

三、生物可降解型热塑性聚氨酯支架的制备以及组织工程应用

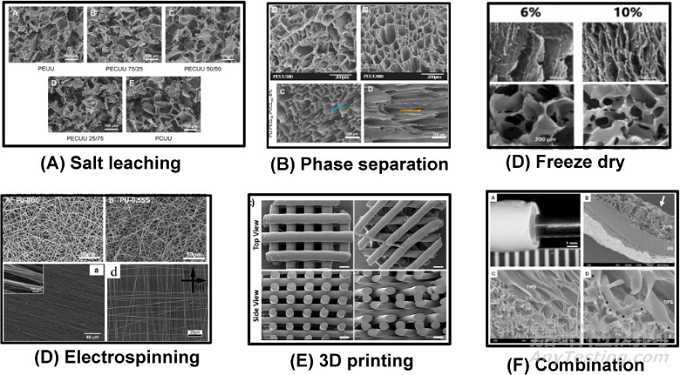

生物可降解型热塑性聚氨酯因其良好的可加工性,可以通过多种方式制备成多孔支架,比如盐析法, 相分离,冻干,静电纺丝,3D 打印等 (图5)。聚氨酯多孔支架也被广泛应用于多种组织的修复和再生。

Fig. 5. Typical morphologies of biodegradable thermoplastic polyurethane scaffolds fabricated by various methods. (A) Salt leaching. Reprinted with permission from [52]. Copyright 2010 Elsevier B.V (B) Phase separation. Top: random pores. Reprinted with permission from [196]. Copyright 2005 Elsevier B.V.; Bottom: aligned pores Reprinted with permission from [197]. Copyright 2020 American Chemical Society. (C) Freeze drying. The aligned (top) and random (bottom) scaffolds were prepared using WBPU emulsion by freeze-drying at different concentrations. Reprinted with permission from [210]. Copyright 2019 Oxford University Press. (D)Electrospinning. Top: random fibers. Reprinted with permission from [31]. Copyright 2015 American Chemical Society. Bottom left. Aligned fibers. Reprinted with permission from [213]. Copyright 2012 Elsevier B.V. Bottom right: orthogonally aligned fibers. Reprinted with permission from [214]. Copyright 2015 Wiley. (E) 3D printing. Melt extrusion printing. Reprinted with permission from [206]. Copyright 2020 Elsevier B.V. (F) Combination. A bilayer scaffold from phase separation and electrospinning. Reprinted with permission from [208]. Copyright 2010 Elsevier B.V.

3.1 聚氨酯支架用于心血管修复

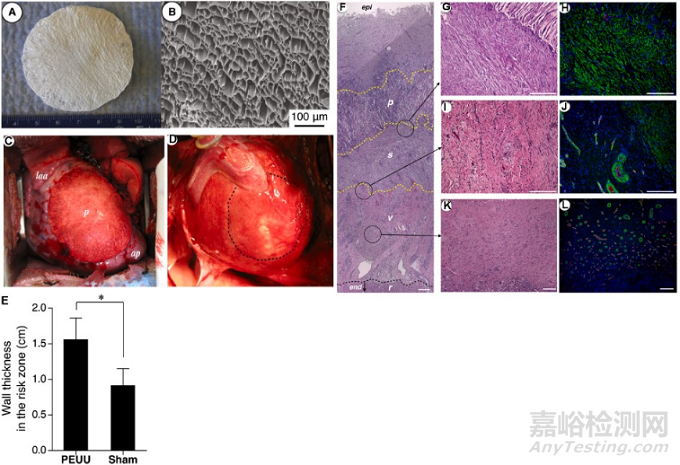

聚氨酯因其优异的力学性能被广泛地用作心肌补片, 血管支架和心脏瓣膜材料。甚至有一些基于聚氨酯的心血管修复产品已然面世, 比如Vectra ® graft, 是一款基于聚醚型聚氨酯的血管支架产品早在2000年已经得到美国FDA认证上市。聚氨酯心肌补片也被植入多种心肌梗死动物模型中,印证了其对于受损心肌功能恢复的促进作用 (图6)。此外,通过加入天然多肽或者蛋白来增加聚氨酯的生物活性,调节改善聚氨酯支架力学性能使其更趋近于天然心肌的力学性能,以及导电聚氨酯的应用都是当前聚氨酯心血管支架的研究方向。另一方面,可降解聚氨酯也被广泛用于小直径血管和瓣膜材料

Fig. 6. Biodegradable polyurethane cardiac patch implanted in a porcine MI model. Digital (A) and SEM (B) images of biodegradable polyurethane cardiac patch. (C) The polyurethane patched left ventricle wall (n = 7) was significantly thicker than the sham surgery wall (n = 8). *p < 0.01. (F) Hematoxylin and eosin staining and immunostaining for a-smooth muscle actin (αSMA) and CD31. The polyurethane patched wall exhibited an aSMA rich layer (s) beneath the implanted PEUU patch (p). Below the αSMA rich layer was a vascular rich layer (v) and then a myocardial remnant (r) region at the endocardial side. A higher magnification of the boundary area between the polyurethane patch and αSMA rich layer showed that the PEUU partially degraded and cellular infiltration occurred with αSMA-positive cells (G and H). (I and J) are the junction between αSMA and vascular rich layers, and (K and L) are the center of the vascular rich layer. Reprinted with permission from [221]. Copyright 2013 American Association for Thoracic Surgery.

3.2 聚氨酯支架用于肌肉骨骼修复

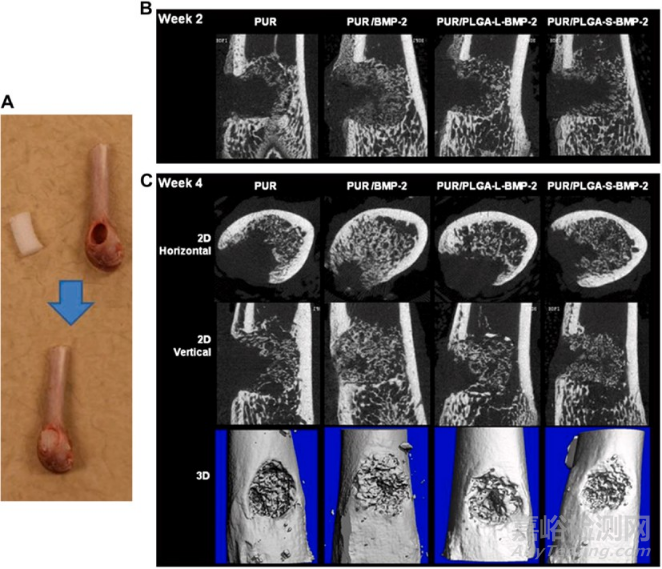

聚氨酯支架也被广泛应用于半月板,骨和软骨的修复。很多可降解聚氨酯半月板支架得以进入临床试验阶段,且实验追踪期不小于五年。实验结果证明聚氨酯半月板可以促进膝关节功能修复,减少疼痛。但是植入失败率高达40%, 且对于软骨的保护能力受到了质疑。聚氨酯支架也被广泛应用于骨修复中,一些生物活性因子 (如骨形态发生蛋白 rhBMP-2)会被加入聚氨酯骨支架中增加其生物活性,从而促进骨损伤修复 (图7)。

Fig. 7. In vivo evaluation of the effects of polyurethane scaffold encapsulating rhBMP-2 on bone reparation in a rat femoral plug model. Four treatment groups included: PUR control (no rhBMP-2), PUR/rhBMP-2 (no PLGA microspheres), PUR/PLGA-L-rhBMP-2 (rhBMP-2 released from large PLGA microspheres), and PUR/ PLGA-S-rhBMP-2 (rhBMP-2 released from small PLGA microspheres). The PUR cylinders (5 mm*3 mm) were implanted into rat femoral plug defects (A) and harvested for mCT imaging at week 2 (B) and 4 (C), respectively. All rhBMP-2 treated groups showed significantly higher new bone formation than the control (PUR) (p < 0.05). Reprinted with permission from [277]. Copyright 2009 Elsevier. Ltd.

3.3 聚氨酯支架用于神经修复

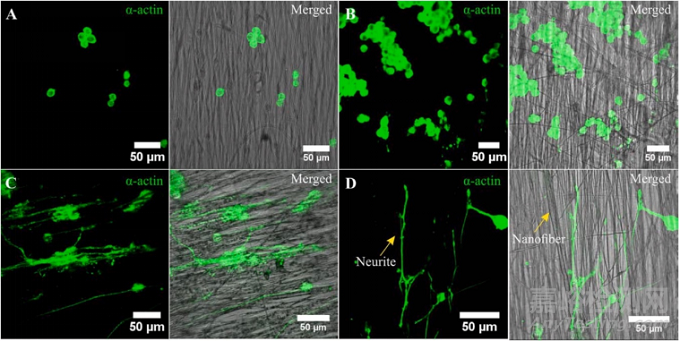

由于神经细胞的电学活性,使得导电性聚氨酯成为极具潜力的神经修复材料。参杂了金纳米粒子的聚氨酯纳米纤维可以促进PC-12 细胞的贴附和增殖。同时在神经生长因子和电刺激下, PC-12细胞神经突的生长和伸长也得到了促进 (图8)。

Fig. 8. PC12 cells growth on (A) polyurethane nanofibers; (B) gold nanoparticle decorated polyurethane nanofibers; (C) gold nanoparticle decorated aligned polyurethane nanofibers; (D) gold nanoparticle decorated aligned PU nanofibers after NGF and electrical stimulation. The neurite elongation of PC-12 cells was significantly promoted on gold nanoparticle decorated aligned PU nanofibers with the synergistic effect of NGF and electrical stimulation. Reprinted with permission from [293]. Copyright 2018 Wiley Periodicals, INC.

3.4 聚氨酯支架用于伤口修复

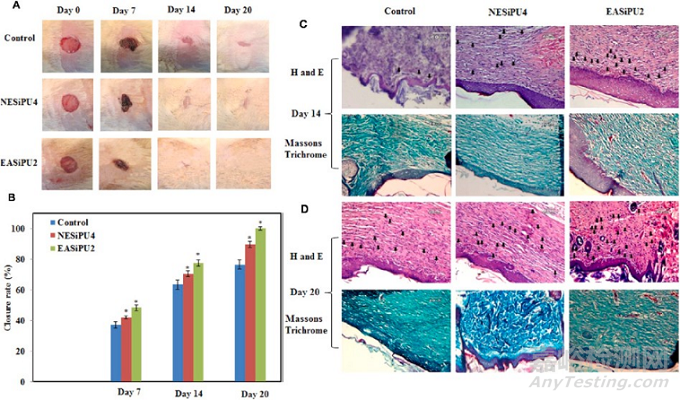

聚氨酯因其良好的氧透过性而被用于伤口修复, 但其抗菌性和亲水性需要得到改善从而阻止细菌感染和提高细胞黏附。提高聚氨酯的抗菌性可以通过引入抗菌物,如金、银、氧化锌、季铵盐、抗生素等得以实现。而亲水性可以通过混入亲水物质或者增加聚氨酯亲水链段组分得到改善。此外,抗氧化物也可以加入聚氨酯中以促进伤口修复进程 (图9)。

Fig. 9. In vivo evaluation of effects of polyurethane/siloxane dressing on wound healing in a rat skin wound model. Two treatment groups include: NESiPU4 (no aniline trimer, nonconductive), and EASiPU2 (containing aniline trimer, conductive). Photographs (A) and closure rate (B) of wounds treated with gauze (control), NESiPU4, and EASiPU2 during the wound healing process for 20 days. *p < 0.05. H&E and Masson’s Trichrome staining at day 14 (C) and day 20 (D). Scale bars: 60 μm. Arrows indicate capillaries. The results suggested that the electroactive wound dressing could promote fast wound healing by complete re-epithelialization of the wound, enhanced vascularization, and collagen deposition. Reprinted with permission from [304]. Copyright 2015 American Chemical Society.

最后作者指出虽然有很多体内体外的实验验证的生物可降解型聚氨酯的良好的生物相容性, 但市面上生物可降解型聚氨酯产品并不多。很多有潜力的可降解型聚氨酯产品在被FDA认证之前仍然还有许多工作需要完成。值得注意的是,对于产品体内体外安全性和功能性的取证一定要形成完善的证据链。此外,本文作者也提出了几个新的可生物降解的聚氨酯研究方向,比如相较于单一功能聚氨酯,多功能性的聚氨酯也许更能满足组织修复的需求。此外,可用于3D 打印的水性/水溶性聚氨酯,以及免疫调节性聚氨酯也是极具潜力的可用于生物医学领域的新型聚氨酯材料。

总之,可降解聚氨酯材料可以通过化学结构设计调节它的物化性质, 力学和生物学性能,以达到组织修复的材料要求。它们也非常有希望用于临床应用。

来源:BioactMater生物活性材料