您当前的位置:检测资讯 > 法规标准

嘉峪检测网 2025-07-28 20:39

近日,EDQM-OMCL发布了《活塞式容量仪器(POVA)确认指南》,该指南描述了用于化学和生物测试的 POVA(如移液器)的要求,包含活塞式容量仪器(如移液枪)使用的最佳实践以及人员确认要求、活塞式容量仪器(如移液枪,包括可更换部件)的选择考虑、使用前考虑、校准要求、校准前的初步检查、计量确认、环境条件、日常测试的一般考虑、活塞式容量仪器(POVA)的评估、合格 / 不合格状态的判定、要求及相关典型接受标准等。

解析如下:

指南将移液枪的测试分为校准和日常测试:

校准:建立交付容量与仪器选定容量之间关系以及相关测量不确定度的一系列操作。校准不需要对仪器进行永久性修改的操作,也不需要对设备进行调整。

日常测试:定期(例如每三个月)进行的分析设备监测或分析质量控制程序。该术语与 “确认(verification)” 同义。

测量不确定度:进行校准时,应评估并报告测量不确定度;而在日常测试中,则是可选的。

使用移液器时,使用人员的移液技术通常是容量误差的最大来源。因此,使用、测试或校准活塞式容量仪器(POVA)的合适人员应接受液体处理工具选择和正确移液技术方面的培训。实验室应建立并记录活塞式容量仪器(POVA,如移液枪)使用人员的能力要求,包括确认和培训要求。使用人员能力可通过日常测试、能力验证或使用人员间比对等方式进行监测。

移液枪的校准前检查:

活塞功能:平稳且可靠。

头座:无痕迹或变形,无液体残留。

泄漏:吸取标称容量 10 秒后,吸头处无液滴形成。

通过目视检查,无内部或外部污染。

应在以下情况对活塞式容量仪器(POVA,如移液枪)进行校准:

收到时(除非供应商已校准);

在移液器使用期间定期进行,且至少每 12 个月一次;

在任何维护、修理或调整之后。

实验室可根据风险评估,考虑进行更频繁和定期的校准

校准资质要求:如校准由服务提供商进行,实验室应确认并选择一家依据 ISO/IEC 17025 获得认可的提供商,以按照 ISO 8655 的要求进行校准;如果校准由实验室内部操作人员进行,应选择合适的校准程序。

文件给出校准程序的要求:

校准应反映日常操作(例如,使用的操作范围;用于移液器校准的吸头最好与日常工作中使用的类型相同 - 对于可灭菌吸头,灭菌程序不应影响吸头的计量特性。

例外情况是移液模式,校准应仅以正向模式进行;反向模式校准不再被接受。

对于日常测试,反向模式是可接受的。

校准必须在受控的环境条件(即温度、湿度和压力)下进行,以尽量减少水的蒸发,尤其是容量低于 50 μL 的移液器。

环境条件要求:

在开始测试前至少 2 小时(最短平衡时间)以及测试期间,测试室的空气温度和相对湿度应在规定的范围内。

|

环境条件 |

ISO 8655 - 6、8* |

ISO 8655 - 7** |

|

测试室温度 |

20 ± 3℃ |

需记录 |

|

测试期间温度变化 |

0.5℃ |

0.5℃,需记录 |

|

2 小时平衡期间温度变化 |

0.5℃/ 小时 |

1℃,需记录 |

|

水 / 测试液体温度 |

环境空气温度 ± 0.5℃ |

需记录 |

|

测试室湿度 |

45 - 80% |

需记录 |

|

大气压力 |

需记录 |

需记录 |

应避免长时间(超过 10 分钟)使用移液器导致其被手捂热。来自手的热传递可能导致热不平衡,并影响移液器气垫的容量。

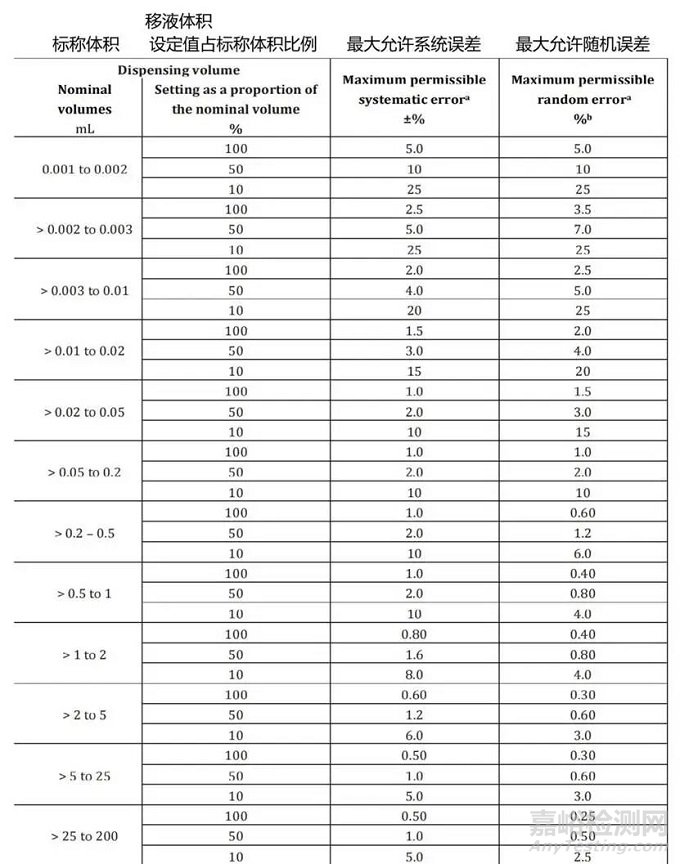

文件给出各种类型移液器的最大允许误差:

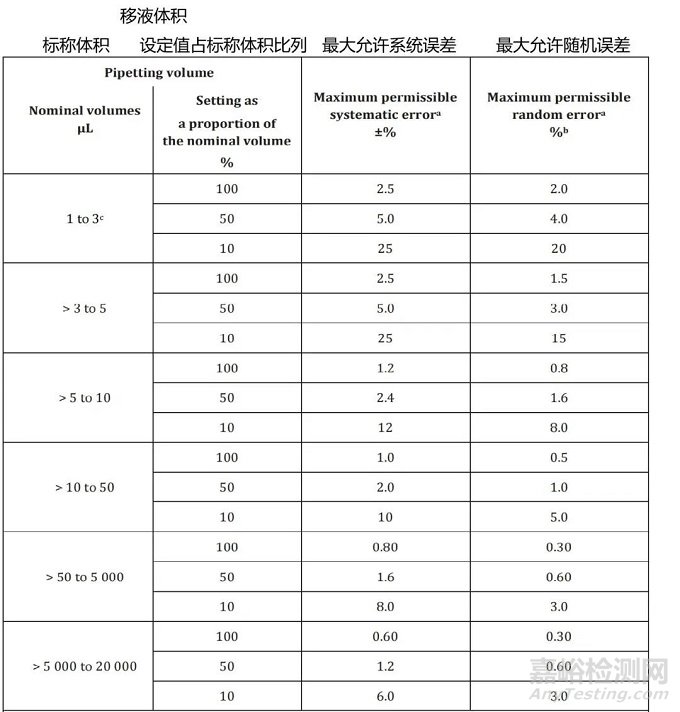

A型和D1型(单通道移液器)的最大允许误差(MPE)

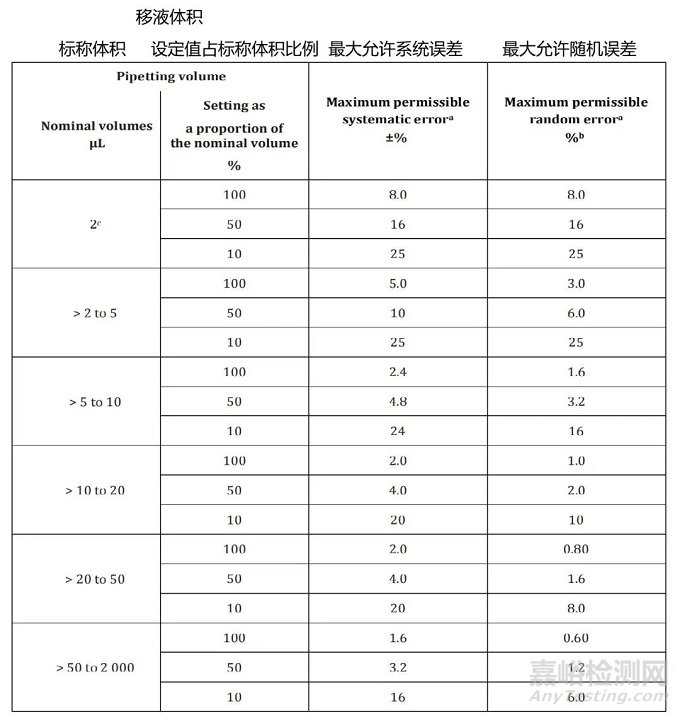

A型和DI型(多通道移液器)的最大允许误差

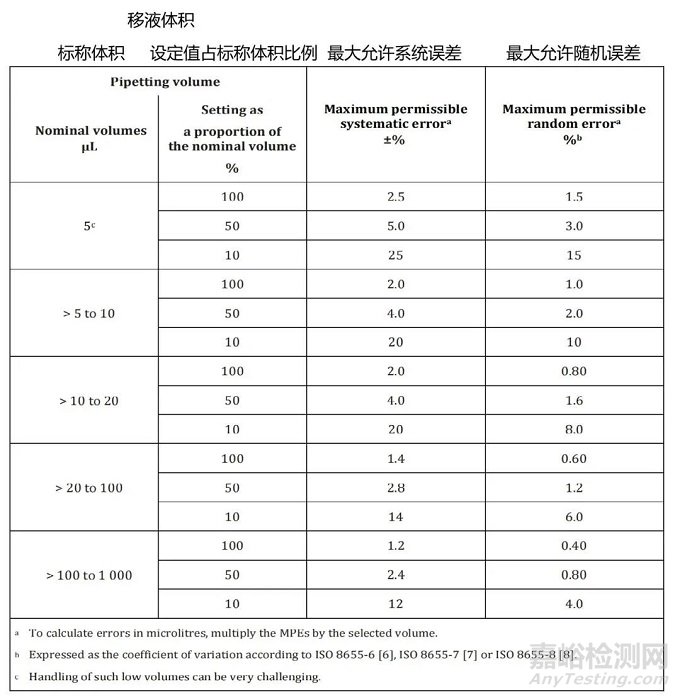

D2型的最大允许误差

单步移液器的最大允许误差

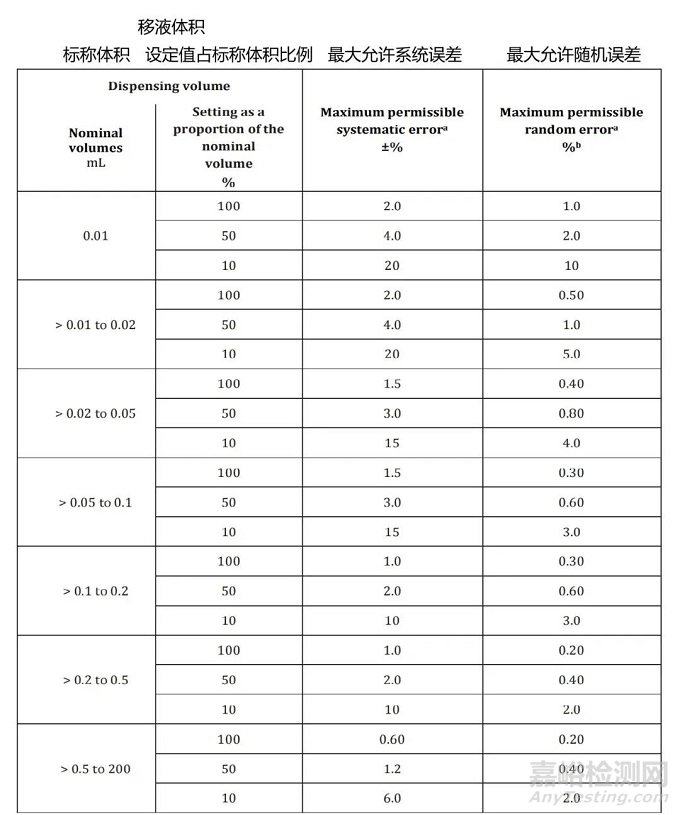

多步递送分配器的最大允许误差

翻译如下:

QUALIFICATION OF PISTON - OPERATED VOLUMETRIC APPARATUS (POVA)活塞式容量仪器(POVA)的确认

Contents目录Introduction引言Aim and Scope of the Guideline指南的目的和范围Glossary (ISO 8655 - 1)术语(ISO 8655-1)Best practices for the use of POVA and requirements for staff qualification活塞式容量仪器(POVA,如移液枪)使用的最佳实践以及人员确认要求General Consideration for LEVEL I on selection of POVA (including exchangeable parts)LEVEL I :活塞式容量仪器(如移液枪,包括可更换部件)选择的一般考虑General Consideration for LEVEL III - Release for useLEVEL III:投入使用的一般考虑General Consideration for LEVEL II - CalibrationLEVEL II:校准的一般考虑7.1 Preliminary checks before calibration7.1 校准前的初步检查7.2 Metrological confirmation7.2 计量确认7.3 Environmental conditions7.3 环境条件7.4 Gravimetric test7.4 重量测试General Consideration for LEVEL IV - Routine testsLEVEL IV - 日常测试的一般考虑8.1 Preliminary checks before routine testing8.1 日常测试前的初步检查8.2 Metrological confirmation8.2 计量确认POVA Evaluation活塞式容量仪器(POVA)的评估9.1 Determination of pass/fail status9.1 合格 / 不合格状态的判定9.2 Non - conformity of pipettes9.2 移液器的不符合项9.3 Calibration/report9.3 校准 / 报告9.4 Requirements and related typical acceptance criteria9.4 要求及相关典型接受标准

Introduction引言

The present document is the 6th Annex of the core document "Qualification of Equipment" [1], and it should be used in combination with it when planning, performing and documenting the qualification of piston - operated volumetric apparatus (POVA).本文件是核心文件 “设备确认”[1] 的第 6 个附录,在规划、实施和记录活塞式容量仪器(POVA)的确认时,应与该核心文件结合使用。

The core document "Qualification of Equipment" contains the Introduction and general forms for Level I and II of qualification, which are common to all types of instruments.核心文件 “设备确认” 包含引言以及LEVEL I 和LEVEL II 确认的通用表格,他们对所有类型的仪器都是通用的。

Level III and IV testing must be carried out, as an ISO/IEC 17025 [2] requirement, by trained personnel.根据 ISO/IEC 17025 [2] 的要求,LEVEL III 和LEVEL IV测试必须由经过培训的人员进行。

This Guideline has been elaborated according to the standard ISO 8655 (Parts - 1, - 2, - 5, - 6, - 7, - 8 and - 10) [3 - 9]. Requirements and (if applicable) corresponding acceptance criteria should be applied; however, other appropriately justified deviations are acceptable provided they are traceable.本指南是根据 ISO 8655 标准(第 1、2、5、6、7、8 和 10 部分)[3 - 9] 制定的。应应用相关要求以及(如适用)相应的接受标准;然而,可以接受其他经论证的偏差,应可以追溯。

This document describes the method given in ISO 8655-6 "Gravimetric reference measurement procedure for the determination of volume" [6], which is the most commonly used.本文件描述了 ISO 8655 - 6《用于容量测定的重量法参考测量程序》[6] 中给出的方法,这是最常用的方法。

Another reference measurement procedure is described in ISO 8655-8 "Photometric reference measurement procedure for the determination of volume" [8], which is applicable to apparatus with a maximum nominal volume of 5 000 μL.另一种参考测量程序在 ISO 8655 - 8《用于容量测定的光度法参考测量程序》[8] 中描述,其适用于最大标称容量为 5000 微升的仪器。

Alternative procedures are given in ISO 8655-7 "Alternative measurement procedures for the determination of volume" [7].替代程序在 ISO 8655 - 7《用于容量测定的替代测量程序》[7] 中给出。

In this Annex the general requirements for metrological confirmation of POVAs, which comprises calibration and verification, are described, as well as other requirements included in ISO 8655-10 "User guidance, and requirements for competence, training, and POVAsuitability" [9].在本附录中,描述了 POVA(移液器)计量确认的一般要求,包括校准和验证,以及 ISO 8655 - 10《使用人员指南以及能力、培训和 POVA 适用性要求》[9] 中包含的其他要求。

Aim and Scope of the Guideline指南的目的和范围

This guideline describes the requirements for POVAs used in chemical and biological tests irrespective of the mode of operation (manual or electronic).本指南描述了用于化学和生物测试的 POVA(移液器)的要求,无论其操作模式(手动或电动)如何。

Requirements and test procedures are based on the ISO 8655 standard.要求和测试程序基于 ISO 8655 标准。

The following types of pipettes have been considered in this guideline:本指南考虑了以下类型的移液器:

1. Fixed - volume single - channel pipettes (air displacement (type A) and positive displacement or direct displacement pipettes (type D, with a reusable or disposable plunger and capillary)) 1. 固定容量单通道移液器(空气置换式(A 型)和正置换式或直接置换式移液器(D 型,带有可重复使用或一次性活塞和毛细管))

2. Variable - volume single - channel pipettes (air displacement (type A) and positive displacement or direct displacement pipettes (type D1) reusable or (type D2) disposable plunger and capillary) 2. 可变容量单通道移液器(空气置换式(A 型)和正置换式或直接置换式移液器(D1 型可重复使用或 D2 型一次性活塞和毛细管))

3. Fixed - volume multi - channel pipettes (air displacement (type A)) 3. 固定容量多通道移液器(空气置换式(A 型))

4. Variable - volume multi - channel pipettes (air displacement (type A)) 4. 可变容量多通道移液器(空气置换式(A 型))

5. Electronic motorized pipettes 5. 电动移液器

6. Dispensers (e.g. repetitive piston pipettes) 6. 分配器(例如重复活塞移液器)

NOTES:注释:

Although designed as variable - volume pipettes, electronic motorized pipettes may be used in different modes:尽管电动移液器设计为可变容量移液器,但可在不同模式下使用:

Pipetting mode: the selected volume is aspirated and dispensed in forward mode pipetting.

移液模式:以正向移液模式吸取和分配所选容量。

Multi - dispensing mode: the aspirated volume is dispensed repeatedly in a predefined number of aliquots, which can be of equal or different volumes.

多次分配模式:吸取的容量以预定义数量的等分试样重复分配,这些等分试样的容量可以相等或不同。

Mixing mode: pipetting step is followed by a mixing phase, composed of repeated aspirating and dispensing.

混合模式:移液步骤之后是混合阶段,由重复的吸取和分配组成。

Reverse mode: aspiration of the selected volume added with an extra amount of liquid that remains in the tip after the dispensing of the selected volume. The remaining volume can subsequently be discarded.

反向模式:吸取所选容量并额外添加一定量的液体,该液体在分配所选容量后残留在吸头中。剩余容量随后可以丢弃。

Multi - aspirated: aspiration of a predefined number of equal or different volumes, followed by the dispense of the total aspirated volume.

多次吸取:吸取预定义数量的相等或不同容量,然后分配总共吸取的容量。

Additionally, this guideline provides guidance, based on ISO 8655-10 [9] regarding:

此外,本指南基于 ISO 8655 - 10 [9] 提供以下方面的指导:

The selection of POVAs (including best practices for their use);

活塞式容量仪器(POVA,如移液枪) 的选择(包括其使用的最佳实践);

User qualification/re - qualification (requirements for user training and competence);

使用人员确认 / 重新确认(使用人员培训和能力要求);

POVA performance requirements and tolerances to ensure fitness for their intended use;

POVA(移液器)性能要求和公差,以确保符合其预期用途;

Replicate measurements and uncertainty.

重复测量和不确定度。

3. Glossary (ISO 8655 - 1)3. 术语(ISO 8655 - 1)

Calibration: set of operations that establish the relationship between the delivered volume and the corresponding selected volume of the apparatus with associated measurement uncertainties.校准:建立交付容量与仪器选定容量之间关系以及相关测量不确定度的一系列操作。

NOTE:注释:

Calibration requires no operation which permanently modifies the apparatus and does not require adjustment of the device.校准不需要对仪器进行永久性修改的操作,也不需要对设备进行调整。

Routine testing: testing equipment monitoring or analytical quality - control routines to be performed at regular intervals, for example, every three months. Other time intervals may be adopted giving due consideration to the factors described in Level IV (paragraph 8). This term is a synonym of "verification".日常测试:定期(例如每三个月)进行的分析设备监测或分析质量控制程序。在适当考虑 IV 级(第 8 段)所述因素的情况下,可采用其他时间间隔。该术语与 “确认(verification)” 同义。

Measurement uncertainty: non - negative parameter, associated with the delivered volume, that characterises the dispersion of the volumes that could reasonably be attributed to the delivered volume based on the information used.测量不确定度:与交付容量相关的非负参数,用于表征基于所用信息合理归因于交付容量的容量分散性。

When performing calibration, the measurement uncertainty shall be evaluated and reported; however, in routine testing it is optional.进行校准时,应评估并报告测量不确定度;而在日常测试中,则是可选的。

Metrological confirmation: set of operations required to ensure that the POVA conforms to the requirements for its intended use.计量确认:为确保活塞式容量仪器(POVA)符合其预期用途要求所需的一系列操作。

NOTE:注释:

Metrological confirmation generally includes calibration and verification, and any necessary adjustment or repair, and subsequent recalibration, comparison with the metrological requirements for the intended use of the POV A, as well as any required sealing and labelling.计量确认通常包括校准和验证,以及任何必要的调整或维修,随后的再校准,与 活塞式容量仪器(POVA,如移液枪) 预期用途的计量要求进行比较,以及任何必要的密封和贴标签。

Nominal volume: upper limit of the usable volume range as specified by the manufacturer.标称容量:制造商规定的可用容量范围的上限。

NOTES:注释:

For a variable - volume piston - operated volumetric apparatus, the nominal volume corresponds to the maximum volume that can be set by the user and that is specified by the manufacturer.对于可变容量活塞式容量仪器,标称容量对应于使用人员可设置且由制造商规定的最大容量。

For dispensers the nominal volume is depending on the tips used.对于分配器,标称容量取决于所用的吸头。

For the other terms refer to JCGM 200:2012 International vocabulary of metrology - Basic general concepts and associated terms (VIM) [10] and ISO 8655 - 1 [3].其他术语请参考 JCGM 200:2012《国际计量学词汇 - 基本通用概念及相关术语》(VIM)[10] 和 ISO 8655 - 1 [3]。

4. Best practices for the use of POVA and requirements for staff qualification活塞式容量仪器(POVA)的最佳使用实践和人员确认要求

Guidance for the use of the different POV A, pipetting technique, as well as references to best practices for handling non - aqueous liquids are given in ISO 8655 - 10 [9]. Critical aspects to take into account, if applicable, include:ISO 8655 - 10 [9] 给出了不同活塞式容量仪器(POVA)的使用指南、移液技术,以及处理非水液体的最佳实践参考。如适用,需要考虑的关键方面包括:

Setting of the volume;

容量设置;

Pre - wetting of pipette tips/Immersion depth;

移液器吸头的预湿润 / 浸入深度;

Forward and reverse pipetting modes;

正向和反向移液模式;

Thermal equilibrium/Hand warming;

热平衡 / 手温预热;

Tip position during aspiration and dispense/Pause after aspiration;

吸取和分配过程中的吸头位置 / 吸取后暂停;

Velocity of aspiration and delivery;

吸取和排出速度;

Tip wiping/Cleaning/Priming.

吸头擦拭 / 清洁 / 预充。

The ability to consistently deliver precise and accurate volumes is the volumetric performance, it is directly dependent on the system, the POV A and the technique employed by the user of the pipette.始终如一地提供精确准确容量的能力是容量性能,它直接取决于系统、活塞式容量仪器(POVA)以及移液器使用人员采用的技术。

When using pipettes, the user's pipetting technique is usually the largest contributor to volumetric error. Therefore, proper users who use, test or calibrate POV A shall be trained on liquid handling tool selection and proper pipetting techniques.使用移液器时,使用人员的移液技术通常是容量误差的最大来源。因此,使用、测试或校准活塞式容量仪器(POVA)的合适人员应接受液体处理工具选择和正确移液技术方面的培训。

The laboratory shall establish and document the competence requirements for POV A users, including qualification and training requirements.实验室应建立并记录 活塞式容量仪器(POVA,如移液枪) 使用人员的能力要求,包括确认和培训要求。

User competence can be monitored, e.g. by routine testing, proficiency testing or as inter - comparison between users.使用人员能力可通过日常测试、能力验证或使用人员间比对等方式进行监测。

A report of training or competence assessment can be issued to the user, whose content should include:可向使用人员出具培训或能力评估报告,其内容应包括:

Identification of the user

使用人员身份信息

Indication whether it is a training (trainer’s identification) or competence assessment report

表明是培训报告(培训人员身份识别)还是能力评估报告

Identification of the POV A and tips used

所用 活塞式容量仪器(POVA,如移液枪) 及吸头的编号

Environment of test conditions (at least room temperature and air relative humidity – RH)

测试条件的环境(至少包括室温及空气相对湿度 - RH)

Volumes tested

测试的容量

Criteria of the operator competence assessment (e.g. systematic and random errors or uncertainties in use of a single delivered volume for the tested volumes)

操作人员能力评估标准(例如,针对测试容量,使用单次交付容量时的系统误差和随机误差或不确定度)

Reference to ISO 8655 - 10 [9] (and any deviations) as well as the employed test method (e.g. ISO 8655 - 6 [6], ISO 8655 - 8 [8] or any specific test procedure in ISO 8655 - 7 [7])

引用 ISO 8655 - 10 [9](及任何偏差)以及所采用的测试方法(例如 ISO 8655 - 6 [6]、ISO 8655 - 8 [8] 或 ISO 8655 - 7 [7] 中的任何特定测试程序)

Volumetric measurement results for each delivered volume

每个交付容量的容量测量结果

Total number of replicate measurements made for each tested volume, and the number of measurement results used for statistical analysis

每个测试容量的重复测量总数,以及用于统计分析的测量结果数量

Date of test and duration of validation

测试日期和验证持续时间

5. General Consideration for LEVEL I on selection of POV A (including exchangeable parts)5. LEVEL I 活塞式容量仪器(POVA,如移液枪)(包括可更换部件)选择的一般考虑因素

All POV A shall be selected based on their suitability for the intended use. To achieve the best volumetric performance, it is recommended to select a POV A with a nominal volume close to the volume to be delivered. The following factors should be considered when selecting apparatus:所有 活塞式容量仪器(POVA,如移液枪) 应根据其对预期用途的适用性进行选择。为实现最佳的容量性能,建议选择标称容量接近待交付容量的 活塞式容量仪器(POVA,如移液枪)。选择设备时应考虑以下因素:

smallest and largest liquid volume to be delivered;

待交付的最小和最大液体容量;

liquid properties;

液体特性;

the resulting impact of delivering inaccurate volumes;

交付不准确容量所产生的影响;performance requirements (maximum permissible errors – MPEs – and/or process tolerances);

性能要求(最大允许误差 - MPEs - 和 / 或过程公差);

type and size of POV A and its application;

活塞式容量仪器(POVA,如移液枪) 的类型和尺寸及其应用;

single - channel or multi - channel POV A;

单通道还是多通道 活塞式容量仪器(POVA,如移液枪);

delivery of constant volumes during repeated steps;

重复步骤中恒定容量的交付;

frequency of use.

使用频率。

NOTE: Refer to ISO 8655 - 10, Table A.1, for the selection of pipettes.注:移液器的选择请参考 ISO 8655 - 10 的表 A.1。

Exchangeable parts, such as pipette tips, shall be designed to match the design of the POV A. Changes in material, size of tip orifice, taper (angle), dead air volume and retained liquid impacts the performance of the pipetting system. The overall system performance (POVA and exchangeable parts) shall be suitable for its intended purpose.可更换部件,如移液器吸头,应设计成与 活塞式容量仪器(POVA,如移液枪) 的设计相匹配。材料、吸头孔尺寸、锥度(角度)、死腔容量和残留液体的变化会影响移液系统的性能。整个系统性能(POVA 和可更换部件)应适合其预期用途。

NOTE: Refer to ISO 8655 - 10, Table A.2, for the selection of pipette tips.注:移液器吸头的选择请参考 ISO 8655 - 10 的表 A.2。

6. General Consideration for LEVEL II - Release for use6. LEVEL II - 放行使用的一般考虑

Check if all requirements set up during the selection are met and all necessary requirements are covered and fulfilled in the provided certificate.检查在选择过程中设定的所有要求是否得到满足,以及所提供的证书中是否涵盖并满足所有必要要求。

7. General Consideration for LEVEL III - Calibration7. LEVEL III 校准的一般考虑

7.1 Preliminary checks before calibration 7.1 校准前的初步检查

Correct functionality of POV A shall be checked before calibration, as follows:校准前应检查 活塞式容量仪器(POVA,如移液枪) 的功能是否正常,如下所示:

Function of piston: smooth and positive.

活塞功能:平稳且可靠。

Tip holder: no marks or distortions, no liquid residues.

头座:无痕迹或变形,无液体残留。

Leakage: no drop is formed at the tip after 10 seconds from withdrawing the nominal volume.

泄漏:吸取标称容量 10 秒后,吸头处无液滴形成。

No internal or external contamination by visual checking.

通过目视检查,无内部或外部污染。

7.2 Metrological confirmation7.2 计量确认

Some piston pipettes require the use of exchangeable parts during typical use (e.g. disposable or reusable pipette tips), that are considered to be an integral part of the POV A under test.一些活塞式移液器在正常使用过程中需要使用可更换部件(例如一次性或可重复使用的移液器吸头),这些部件被视为被测 活塞式容量仪器(POVA,如移液枪) 的一个组成部分。

The periodic calibration of POV A shall follow a pre - established calibration plan, within the framework of the Quality Management System of the laboratory.活塞式容量仪器(POVA,如移液枪)的定期校准应在实验室质量管理体系的框架内,遵循预先制定的校准计划。

Calibration of the POV A shall be performed:应在以下情况对活塞式容量仪器(POVA,如移液枪) 进行校准:

on receipt (unless already calibrated by the supplier);

收到时(除非供应商已校准);

on a regular basis and at least once every 12 months during the use of the pipette;

在移液器使用期间定期进行,且至少每 12 个月一次;

after any maintenance, repair or adjustment.

在任何维护、修理或调整之后。

As described in ISO 8655 - 1 [3], the laboratory can consider performing more frequent and regular calibrations based on a risk assessment, depending on:如 ISO 8655 - 1 [3] 所述,实验室可根据风险评估,考虑进行更频繁和定期的校准,具体取决于:

the workload of the POV A and number of operators using the pipette;

活塞式容量仪器(POVA,如移液枪) 的工作量以及使用移液器的操作人员数量;

the type of liquids used;

所用液体的类型;

the MPEs selected, depending on the type of use and the accuracy required.

根据使用类型和所需精度选择的最大允许误差(MPEs)。

If calibration is carried out by a service provider, the laboratory shall verify and choose a provider that is accredited in accordance with ISO/IEC 17025 [2] to perform calibrations in accordance with the requirements of ISO 8655.如果校准由服务提供商进行,实验室应确认并选择一家依据 ISO/IEC 17025 [2] 获得认可的提供商,以按照 ISO 8655 的要求进行校准。

If the calibration is performed by internal laboratory operators, the appropriate procedure for calibration shall be selected. Using the gravimetric (ISO 8655 - 6 [6]) or photometric (ISO 8655 - 8 [8]) measurement procedures, the laboratory shall be equipped with suitable balances, in relation to the volume of POV A to be calibrated, or spectrophotometers (plus density and pH meters).如果校准由实验室内部操作人员进行,应选择合适的校准程序。使用重量法(ISO 8655 - 6 [6])或光度法(ISO 8655 - 8 [8])测量程序时,实验室应配备与待校准 活塞式容量仪器(POVA,如移液枪) 容量相适应的合适天平,或配备分光光度计(以及密度计和 pH 计)。

If the above cannot be fulfilled, the laboratory should consider sub - contracting calibration to an accredited service provider or proceed with alternative measurement procedures for determination of volume as described in ISO 8655 - 7 [7].如果无法满足上述要求,实验室应考虑将校准工作分包给一家认可的服务提供商,或采用 ISO 8655 - 7 [7] 中所述的替代容量测量程序。

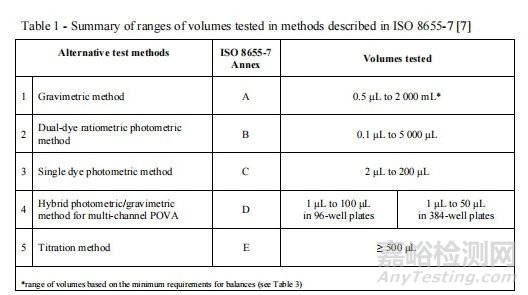

ISO 8655 - 7 includes five test methods and the corresponding test procedures, described in Annex A to Annex E [7]. These methods are suitable for various maximum nominal volumes of POV A (see Table 1) and should be appropriately selected by the user, taking into account that they apply to complete systems comprising the basic apparatus and tips.ISO 8655 - 7 包含五种测试方法以及相应的测试程序,在附录 A 至附录 E [7] 中有描述。这些方法适用于各种最大标称容量的 活塞式容量仪器(POVA,如移液枪)(见表 1),用户应适当选择,同时要考虑到这些方法适用于包括基本设备和吸头的完整系统。

For calibrations, no less than ten replicate measurements per selected volume shall be performed. Measurement procedures and test conditions shall be validated for their suitability by comparison to one of the reference measurement procedures described in ISO 8655 - 6 [6] or ISO 8655 - 8 [8].在校准时,对于每个选定的容量,应进行不少于十次的重复测量。测量程序和测试条件应通过与 ISO 8655 - 6 [6] 或 ISO 8655 - 8 [8] 中所述的参考测量程序之一进行比较,来验证其适用性。

表I - ISO 8655-7[7]中所述方法所测试容量范围汇总

|

替代测试方法 |

ISO 8655 - 7 附录 |

测试容量 |

|

1. 重量法 |

A |

0.5 微升至 2000 毫升 * |

|

2. 双色比率光度法 |

B |

0.1 微升至 5000 微升 |

|

3. 单色光度法 |

C |

2 微升至 200 微升 |

|

4. 多通道 POVA 的混合光度 / 重量法 |

D |

在 96 孔板中为 1 微升至 100 微升;在 384 孔板中为 1 微升至 50 微升 |

|

5. 滴定法 |

E |

≥500 微升 |

* 基于天平最低要求的容量范围(见表 3)

Test conditions, equipment and procedure impact the uncertainty of measurement.测试条件、设备和程序会影响测量的不确定度。

In addition, calibration shall be carried out to reflect routine operation (e.g. operational range of use; tips used for the calibration of pipettes should preferably be the same type as those used in daily work - in the case of sterilizable tips, the sterilization procedures shall not affect the metrological characteristics of the tips (ISO 8655 - 2 [4])). The exception is pipetting mode, where calibration shall only be performed in forward mode; calibration in reverse mode is no longer acceptable.此外,校准应反映日常操作(例如,使用的操作范围;用于移液器校准的吸头最好与日常工作中使用的类型相同 - 对于可灭菌吸头,灭菌程序不应影响吸头的计量特性(ISO 8655 - 2 [4]))。例外情况是移液模式,校准应仅以正向模式进行;反向模式校准不再被接受。

For routine testing, reverse mode is acceptable.对于日常测试,反向模式是可接受的。

If the laboratory is working with infectious materials, decontamination (e.g. disassembling) should be done before calibration, according to the instructions provided by the manufacturer.如果实验室正在处理传染性材料,应根据制造商提供的说明在校准前进行去污。

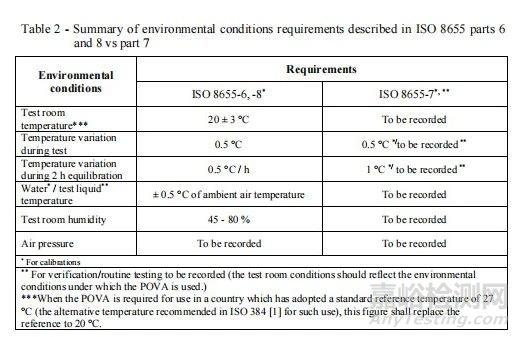

7.3 Environmental conditions7.3 环境条件

Ambient conditions (i.e. air temperature, RH, atmospheric pressure and water temperature) may influence weighing of the dispensed volume and water density (Z - factor); therefore, the calibration results can be impacted.环境条件(即空气温度、相对湿度、大气压力和水温)可能会影响所分配容量的称重和水的密度(Z 因子);因此,校准结果可能会受到影响。

As a result, calibration must be performed under controlled environmental conditions (i.e. temperature, humidity and pressure) to minimize the evaporation of water, which is critical for pipettes with dispensing volumes lower than 50 μL.因此,校准必须在受控的环境条件(即温度、湿度和压力)下进行,以尽量减少水的蒸发,这对于分配容量低于 50 μL 的移液器至关重要。

Apart from the geometry of the weighing vessel (gravimetric method), the test cycle time (time required to complete the weighing of one delivered volume) is important and shall be kept to a minimum.除了称重容器的几何形状(重量法)之外,测试循环时间(完成一次交付容量称重所需的时间)也很重要,应尽量缩短。

Environmental condition requirements are given in Table 2.环境条件要求见表 2。

Air temperature and RH shall be within the specified limits for the test room for at least 2 h before starting the test (minimum equilibration time) and during the test itself.在开始测试前至少 2 小时(最短平衡时间)以及测试期间,测试室的空气温度和相对湿度应在规定的范围内。

表2 - ISO 8655第6部分和第8部分与第7部分所述环境条件要求汇总

|

环境条件 |

ISO 8655 - 6、8* |

ISO 8655 - 7** |

|

测试室温度 |

20 ± 3℃ |

需记录 |

|

测试期间温度变化 |

0.5℃ |

0.5℃,需记录 |

|

2 小时平衡期间温度变化 |

0.5℃/ 小时 |

1℃,需记录 |

|

水 / 测试液体温度 |

环境空气温度 ± 0.5℃ |

需记录 |

|

测试室湿度 |

45 - 80% |

需记录 |

|

大气压力 |

需记录 |

需记录 |

用于校准 / 日常测试时需记录(测试室条件应反映使用 活塞式容量仪器(POVA,如移液枪) 的环境条件)。

用于 活塞式容量仪器(POVA,如移液枪) 验证时。

当在采用 27℃作为标准参考温度的国家需要重复使用 活塞式容量仪器(POVA,如移液枪) 时,应使用 ISO 384 [1] 中推荐的替代温度代替该数值。

7.4 Gravimetric test7.4 重量测试

The principle of the gravimetric method is described in ISO 8655-6 [6].重量法的原理在 ISO 8655 - 6 [6] 中有描述。

If the selected volume is lower than 50 μL, the effect of the evaporation of the water used is significant.如果所选容量低于 50 微升,所用的水的蒸发影响是显著的。

Therefore, the loss of mass should be taken into account in the calculation.因此,在计算中应考虑质量损失。

Settings:设置:

The laboratory where the calibration is performed shall be draught free, with RH of 45 - 80 %.进行校准的实验室应无气流,相对湿度为 45 - 80%。

If volumes lower than 50 μL are selected, an evaporation trap or an open vessel containing water shall be placed inside the balance chamber, and the test cycle time shall be kept to a minimum.如果选择低于 50 微升的容量,应在天平室内放置一个蒸发阱或一个盛水的敞口容器,并且测试周期时间应保持最短。

In addition, the temperature of the laboratory shall be 20 ± 3 °C and stable within ± 0.5 °C during calibration.此外,在校准期间,实验室温度应为 20 ± 3°C,且在 ± 0.5°C 范围内保持稳定。

All the material needed for the test (glassware, water, exchangeable parts, etc.) must be equilibrated for at least 2 h in the room where the test is to be performed.测试所需的所有材料(玻璃器皿、水、可更换部件等)必须在进行测试的房间内平衡至少 2 小时。

If using a variable - volume POV A, select the test volume; this setting shall not be altered during the test cycle of all replicate measurements.如果使用可变容量的 活塞式容量仪器(POVA,如移液枪),选择测试容量;在所有重复测量的测试周期内,此设置不得更改。

Equipment:设备:

An analytical balance with appropriate characteristics shall be used depending on the selected volume of the POV A under test (according to ISO 8655 - 6 [6]), as given in Table 3.应根据被测 活塞式容量仪器(POVA,如移液枪) 的所选容量(根据 ISO 8655 - 6 [6]),使用具有适当特性的分析天平,如表 3 所示。

来源:GMP办公室