在药企环境中实施医疗器械QMS体系需要认真考量及规划,才能第一次就把事情做对,避免任何延误或额外成本。

因此,对现有的过程、能力和体系进行完整评估很关键,借此可以识别任何差距,以及能够用来建立医疗器械QMS体系的资源。由药品QMS体系延伸至医疗器械QMS的建立,优势在于能够利用现有的过程和资源。通过独立认证机构获得ISO 13485质量管理体系认证能够加速、协调MDR审核过程,无需向公告机构展示所有的产品设计或文件资料。

完整评估需囊括企业内部能力,确保企业具备与管理和维护QMS体系对口的专业知识。至于医疗器械的研发和上市后监督,企业需要配备具有生物技术、生物医药、工程、软件等相关背景的专业人才。换句话说,一家提供组合产品的企业需要保证雇员的组成囊括所有必要的专业领域,从而同时覆盖药品和器械,持续更新QMS体系。

如何设计策略,实施医疗器械QMS?

制药企业须先建立一个多职能项目团队,包含必要的医疗器械专家,来处理不同方面的事项。在很多情况下,企业会通过第三方机构来进行评估,制定实施计划。

考虑到药品QMS的文件层级,高级别程序文件,比如制度文件,通常能够同时用于器械和药物,因为这些文件通常不包含过程细节以及执行阶段的角色和职责。比如纠正及预防措施(CAPA)以及投诉管理过程,制度的要素对于药物和器械而言是相似的,而具体执行则涉及不同的专业知识和体系。

部分过程需要提升,确保能够健全地适用于药品和医疗器械。例如,风险管理过程可能需要不同的专业知识和风险分析方法论,来处理产品的机械部分。药品的风险分析主要关注人体内的分子和化学相互作用,与副作用相关。医疗器械的风险分析则关注器械的设计和用户及患者对器械的使用,与意外事件有关,因为医疗器械通常涉及更加复杂的系统。然而,两者的高级别过程是相似的,风险管理团队会评估产品、对潜在风险进行评分并设计解决方案,尽量减少对患者的影响。

高级别的程序文件和部分过程可用于不同类型的产品,而一些低级别的过程可能更容易分开管理。例如投诉管理过程,如果有分别对应药品和医疗器械的规程或工作指引,投诉管理将会更加容易。这与收到的投诉类型有关。对于药品,大多数的投诉与不良事件和副作用有关。对于医疗器械,收到的大多数投诉通常是质量投诉,在报告的时间点不一定对患者有影响。因此,投诉的评估需要不同的专业知识,涉及不同的过程。医疗器械通常需要对器械的设计和操作进行技术评估,而药品投诉的评估则需要医学/临床知识。所以说,配备合适的专业人员,确保进行了适当的调查,是至关重要的。

法规专家角色的区别

医疗器械QMS与药品QMS的要求有所重叠,但也存在一些明显的不同之处。我们选择其中一项要求(法规专家的角色)作为示例,分析其中的共性和区别。

医疗器械和药品的QMS体系都要求配备质量管理代表,对QMS的有效性负责,法规也对这些特定的角色进行了定义。根据欧盟MDR和MPD,企业须为器械任命至少一位监管合规负责人(PRRC),为药品配备一名符合条件的药物警戒负责人(QPPV)和至少一名质量负责人(QP)。监管合规负责人、药物警戒负责人和质量负责人在质量管理和产品安全方面发挥关键作用,但承担的职责存在较大区别。对于药品,药物警戒负责人负责监督和审核药品的安全性,质量负责人负责保证药品的安全性、质量(批次控制)和疗效。对于医疗器械,监管合规负责人对医疗器械的安全性、质量和监管合规负责,这似乎结合了药物警戒负责人和质量负责人的角色。

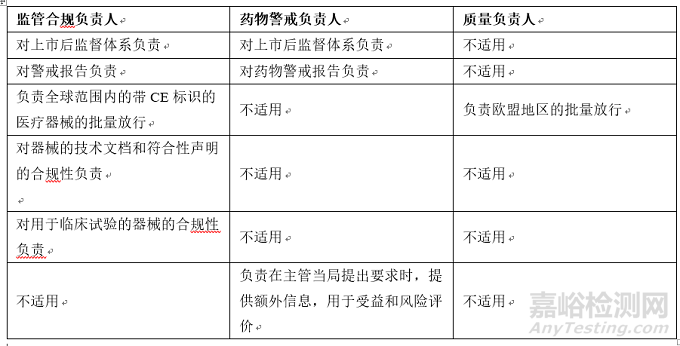

表1:根据欧盟MDR和MPD,监管合规负责人、药物警戒负责人和质量负责人的监管职责概览

如上表所示,尽管这三个角色均负责确保产品的安全性、质量和有效性符合相关法规,各角色的职责范围又各不相同。因此,必须要有清晰的岗位描述和过程,确保相关职责得到了充分的履行。

结论

制药企业在研发组合产品时,实施医疗器械QMS体系会带来明显的优势。然而,这需要仔细的考量和策略性的规划。针对新器械/未来器械的新能力(包含相应专业知识)、允许专业人员根据相关要求执行任务的新过程,以及处理医疗器械要求的新IT系统,都会是制药企业实施医械QMS体系的必需项。因此,利益相关者的管理在整个过程(从规划到实施)都至关重要。此外,制药企业将需要与相关区域的不同监管机构以及公告机构(欧盟)建立新的关系。

英文原文

The global market for drug-device combination products is booming; it was valued at $118.13 billion in 2021 and is expected to expand at a compound annual growth rate of 8.8% by 2030. To capture the growing market with minimal business disruption, most pharma companies used to rely on third parties to develop and obtain the regulatory approval for the device in a combination product, a product that combines a medicinal product or substance and a medical device in a single integral unit (e.g., prefilled syringes). However, pharma companies are now building the capability to manufacture combination products in-house to increase flexibility and reduce dependency on third parties when ensuring the safety and efficacy of the combination product. Therefore, pharma companies have begun to expand their quality management systems (QMS) to allow them to become the legal manufacturer of the medical device components of their combination products. A QMS is a structured system that includes policies, processes, and procedural documents that a pharmaceutical or medical device manufacturer has in place throughout the product’s life cycle. Implementing a QMS that supports medical devices is an essential step in building the new capabilities and becoming a legal manufacturer of such devices.

This will also enable pharma companies to manufacture personalized treatments that maximize positive health outcomes and system resilience, which is a market that will increase by $70 billion to $390.4 billion by 2030. In this article we discuss the challenges and considerations for companies that are interested in entering the EU market with combination products.

How Are Combination Products Regulated?

Combination products are governed by Regulation (EU) 2017/745 (EU MDR) as a medical device or by the Medicinal Products Directive 2001/83/EC (MPD) as a drug, depending on the principal mode of action.

The EU Medical Device Coordination Group (MDCG) recently published guidance document MDCG 2022-5, Guidance on borderline between medical devices and medicinal products under EU MDR, providing additional information for manufacturers when deciding the regulatory status of a combination product.

When a combination product is considered a drug, and thus regulated under the MPD, the medical device in the combination still needs to meet specific requirements of EU MDR. Examples of combination products regulated as medicinal products are prefilled syringes (e.g., vaccine in a prefilled syringe) and single-use inhalers. Having a QMS that complies with both pharma and device regulatory requirements will ensure that the combination product will meet the requirements of both regulations.

Advantages Of Implementing A Medical Device QMS

The major benefit of having a medical device QMS is that the device development and related documentation will comply with the applicable regulatory requirements and the company can CE mark1 the device to demonstrate compliance of the device with EU MDR requirements. The letters “CE” signify that products sold in the European Economic Area (EEA) have been assessed to meet high safety, health, and environmental production requirements.

When a device is developed and CE marked by a third party, the pharma company has less oversight of the process and timelines. By becoming a legal manufacturer of medical devices, the pharma company can CE mark the devices by issuing a Declaration of Conformity per their own project plan and will be less dependent on third parties.

If the device is not CE marked or the device is high-risk, the company has to submit a dossier to a Notified Body to obtain a Notified Body Opinion that will be part of the Marketing Authorization Application (MAA) for the combination to the European Medicines Agency (EMA). The EMA will expect the submission to comply with EU MDR requirements. Having a medical device QMS in place will ensure the documentation will meet the Notified Body’s expectations.

The advantage of CE marking the device, however, is that it eliminates the need for a Notified Body opinion and takes this approval out of the critical path to submission. The only documentation to be submitted as part of the MAA is the Declaration of Conformity issued by the legal manufacturer, in this case the pharma company.

Combination products are often accompanied by an app to enhance the patient’s or healthcare professional’s experience. Depending on the features of the app, it can also qualify as medical device software (SaMD) and will need CE marking to be marketed in the EU. Having a medical device QMS in place will allow a pharma company to develop and CE mark both the device in the combination and the stand-alone app.

Considerations For Implementing A Medical Device QMS In A Pharmaceutical Environment

Implementing a medical devices QMS in a pharmaceutical environment requires careful consideration and planning to do it right the first time and avoid any delays or additional costs.

Therefore, it is key to perform an end-to-end assessment of the existing processes, capabilities, and systems to identify any gaps, as well as the resources that can be leveraged to build a medical device QMS. Building the medical device QMS as an extension of the pharma QMS has the advantage that existing processes and resources can be leveraged. Obtaining ISO 13485 certification for the QMS from an independent certification body can accelerate and harmonize the MDR auditing process, without showing all the product design and documentation to the NB.

The end-to-end assessment needs to include the in-house capabilities to ensure the company has the right expertise to manage and maintain the QMS. For medical device development and post-market surveillance, the company will require experts with biotechnology, biomedical, engineering, software, and related backgrounds. In other words, a company with combination products in its portfolio will need to ensure the employee portfolio includes all necessary expertise to cover both medicinal products and medical devices, so they can keep the QMS up to date.

How To Design A Strategy To Implement A Medical Device QMS

The pharma company must start with a multifunctional project team representing the various parts of the business, including the necessary medical device experts. In many cases, companies will leverage third parties to perform the assessment and to develop the implementation plan.

When considering the document hierarchy of a pharma QMS, the high-level procedural documents, such as policy, can usually be leveraged across devices and drugs because they typically do not contain the details of the process and roles and responsibilities at the execution level. Taking the CAPA (corrective and preventive action) and the complaint management processes as examples, the policy elements will be similar across drugs and devices, whereas the execution will involve different expertise and systems.

Some processes will require enhancement to ensure they are robust across drugs and devices. For example, the risk management process may require different expertise and risk analysis methodologies to address the mechanism of the product. Risk analysis of a medicinal product will mostly focus on the molecular and chemical interaction in the human body associated with a side effect. Risk analysis of a medical device will focus on the design and its use by both the user and the patient in relation to an incident, as medical devices often involve more complex systems. However, the high-level process is very similar for both, as the risk management team will assess the product, score the potential risks, and design a solution to minimize the impact on a patient.

While high-level procedural documents and some processes can be leveraged across different types of products, some lower-level processes may be easier to manage separately. For example, the complaint management process will be easier to manage if there are separate procedures or work instructions for medicinal products and medical devices. This is related to the type of complaints received. For pharma, most of the complaints are related to adverse events and side effects. For medical devices, most of the complaints received are typically quality complaints that do not necessarily have an impact on a patient at the time of reporting. Therefore, complaint evaluation will require different expertise and different processes. Medical devices will typically require a technical assessment of the device’s design and operation, while a medicinal product complaint assessment will require medical/clinical expertise. Therefore, it is essential to have the right experts to ensure a proper investigation is conducted.

Differences In The Regulatory Experts’ Roles

A QMS for medical devices overlaps with pharma QMS requirements but with some significant differences. We use one of the requirements — the regulatory expert’s role — as an example to highlight the commonalities and differences.

Both medical device and medicinal product QMSs require a quality management representative who is responsible for the effectiveness of the QMS; these specific roles are also defined in the regulations. Under the EU MDR and MPD, companies are required to appoint at least one Person Responsible for Regulatory Compliance (PRRC) for devices and have a Qualified Person for Pharmacovigilance (QPPV) and at least one Quality Person (QP) at their disposal for drugs. The PRRC, QPPV, and the QP play key roles in managing the quality and safety of the products, but their responsibilities are quite different. In pharma, the QPPV has the responsibility to monitor and review the safety profiles of the medicinal products and the QP is responsible for assuring the safety, quality (batch control), and efficacy of the medicinal product. For medical devices, the PRRC is responsible for the safety, quality, and regulatory compliance of the medical devices, which seems to be a combination of the roles of the QP and the QPPV.

Table 1: An overview of the regulatory obligations of the PRRC, QPPV, and QP per EU MDR and MPD.

Although all three roles are responsible to ensure the safety, quality, and efficacy of the product comply with the relevant regulations, the scope of each role is quite different, as listed in the table above. Therefore, it is essential to have clear job descriptions and processes in place to ensure the roles are duly fulfilled.

Conclusion

Implementing a medical device QMS in a pharma company will bring significant advantages when developing combination products. However, it needs careful consideration and strategic planning. It will require implementing new capabilities with the right expertise on the new/future medical devices, new processes that will enable the experts to execute in line with the requirements, and new IT systems to address medical device requirements. Therefore, stakeholder management will become essential throughout the entire process, from planning to implementation. In addition, a pharma company will need to establish new relationships with different regulatory groups in a territory and with a Notified Body (EU).

https://www.meddeviceonline.com/doc/combination-product-qms-requirements-for-pharma-companies-entering-the-eu-market-0001

来源:MED DEVICE ONLINE

作者:Hilde Viroux、Maggie Chan和Ruby Powell,均来自PA Consulting

翻译:奥咨达