您当前的位置:检测资讯 > 法规标准

嘉峪检测网 2025-04-22 20:20

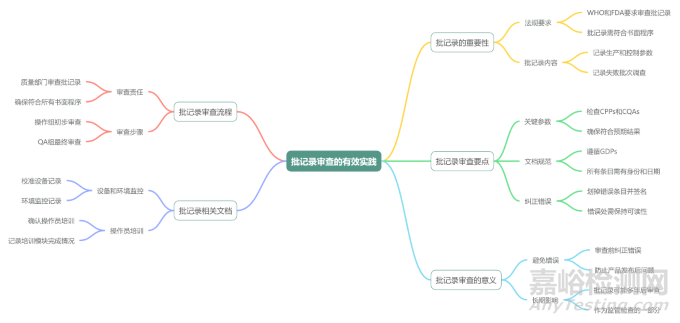

Batch Records: who needs to review?

批记录:谁来审核?

The QualifiedPerson (QP) often reviews the batch documentation personallyprior to certification of a batch. But is the QP obliged to doso? No, because this is not a requirement.

质量受权人 (QP) 通常在批放行之前亲自审核批记录。但 QP 是否有义务这样做?不, 因为这不是要求。

Chapter 2 ofthe EU-GMP Guide (Personnel) states that a QP "must ensure that eachbatch has been manufactured and checked in compliance with the laws … and inaccordance with the requirements of the marketing authorisation."(2.6)

欧盟 GMP 指南第2章《人员》规定, QP“必须确保每批产品的生产和检验都符合法律规定和上市许可的要求。”(2.6)

Chapter 4 ofthe EU-GMP Guide (Documentation) adds that "allrecords should be available to the Qualified Person" (4.27). Itdoesn't say that the QP must review them in any case. According to 4.20i abatch processing record must be approved "by the person responsible forthe processing operations".

欧盟GMP指南第四章《文件》规定 "所有记录都应能提供给质量受权人" (4.27)。但它并没有说 QP 在任何情况下都必须对它们进行审查。根据 4.20 i, 批记录必须得到 "对该工艺作业负责的人员" 的批准。

Who shouldreview the batch documentatoion?

谁应该审查批记录?

The head of theProduction Department needs "to ensure that the production recordsare evaluated and signed by an authorised person" (2.7iii). So thefirst review has to be done by production personnel, a second one might be doneby a quality function that has the competence and is authorised to do so. Ashort review by assistants to the QP based on a checklist could be an option.Annex 16 to the EU-GMP Guidelines states that the QP is responsible forensuring that "all records are complete and endorsed by appropriatepersonnel" (1.7.11). However, a "system should be inplace to indicate special observations and any changes to critical data"(4.27). So the QP should easily see if there have been any non-conformances orchanges in the manufacturing process before certifying a batch. The QP shouldalso be able to rely on the systems and know what is going on in production andquality control.

生产部门负责人需要 "确保生产记录得到经批准人员的评估和签署" (2.7iii)。因此, 必须由生产人员进行初审, 然后可能由具有能力并获得批准的质量人员来完成。QP 助理可根据一份检查清单进行简短的审查。欧盟GMP附录16规定, QP 有责任确保 "所有记录完整并得到适当人员的签署" (1.7.11)。但是, "应建立一个系统用于展示特定偏差和对关键数据的任何修改" (4.27)。因此, 在批放行之前, QP 必须能很容易地看到生产过程中是否有任何不符合项或变更。QP 还应该能够依靠这些系统, 了解生产和质量控制方面发生了什么。

The U.S. Foodand Drug Administration FDA sees the Quality Control Unit (QCU) as beingresponsible to "review records to assure that no errors haveoccurred" (CFR 211.22). The QCU also has the "responsibilityfor approving or rejecting all procedures or specifications." CFR211.192 requires that all drug product production and control records arereviewed and approved by the QCU to determine compliance with writtenprocedures before a batch is released or distributed.

美国FDA认为, 质量控制单元 (QCU) 负责 "审查记录, 以确保没有发生错误" (CFR211.22)。QCU 还 "负责批准或拒绝所有规程或标准"。CFR 211.192 要求所有药品生产和控制记录都经过 QCU 的审查和批准, 以确定在批放行或分发之前是否符合书面规程。

By the way,according to Chapter 4, batch documentation must be kept at least five yearsafter certification of the batch by the Qualified Person (or for one year afterexpiry of the batch, whichever is longer).

同时, 根据第4章, 批记录必须在质量受权人放行之后至少保存五年 (或有效期后一年, 以较长者为准)。

来源:GMP办公室